|

|||

|

|

|||

| ||||||||||

|

|  MIL-W-52125B

3.11.3.1 Wire. All screen cloth shall be made of crimping-grade, oil-tempered standard

heavy wire conforming to NSGA Circular No. 80, table 3, grade B, carbon range 0.55 to 0.70,

drawn and hardened. Wire size shall be as shown in table I.

3.11.4 Vibrating mechanism. A mechanical vibrating mechanism shall be provided for

activating the live frame. When material from the deck or decks of the screen impinges on the

activating mechanism, the mechanism shall be equipped with a replaceable, protective cover.

The mechanism shall be driven by a 15-hp electronic motor.

3.11.4.1 Shaft bearings. The vibrating screen shall have double-row, self-alining,

antifriction shaft bearings. All bearings exposed to dust shall be provided with labyrinth grease

and dust seals.

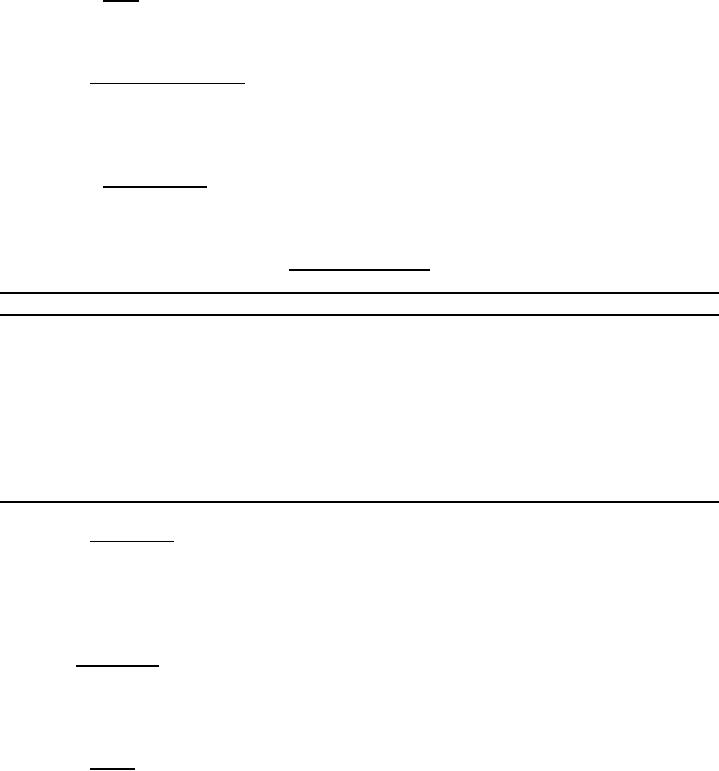

Table I. Wire sizes

Clear opening (minimum)

Wire diameter

(Inch)

(Inch)

2-1/2

1/2

2

7/16

1-1/2

3/8

1

5/16

3/4

1/4

1/2

0.192

3/8

0.162

1/4

0.135

3.11.5 Spray pipes. The vibrating screen shall be equipped with spray pipes above each

screen deck. Each spray pipe shall contain a multiple number of spray nozzles directed

downward. The spray pipes shall receive water under pressure from the main water header

controlled by a valve and shall be provided with valves for regulating the flow or water for each

deck.

3.12 Dehydrator. The unit shall be provided with a dehydrator for fines. The dehydrator

shall have a single screw 30 inches in diameter and a tub approximately 22 feet in length, set at

an angle not more than 20 degrees from the horizontal. The screw shall be driven by a 10-hp

electric motor. A means shall be provided to flush water through the drain trough of the tub.

3.12.1 Screw. The dehydrator screw shall be equipped with replaceable, segmental, iron or

steel castings or weldments having a hardness of not less than 430 Brinell. The upper end of the

screw shaft shall be mounted on thrust-type antifriction bearings enclosed in an oiltight case

18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |