|

|||

|

Page Title:

Table VI. Minimum Charpy V-notch impact requirements (at -40F 2F) |

|

||

| ||||||||||

|

|  MIL-A-12560H (MR)

w/INT. AMENDMENT 4

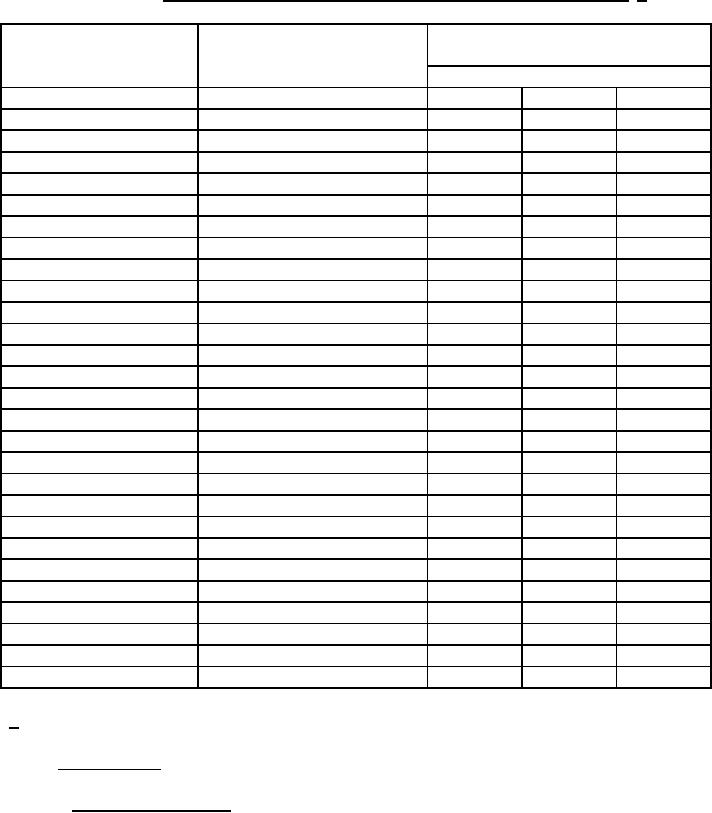

TABLE VI. Minimum Charpy V-notch impact requirements (at -40F 2F). 1/

Average Brinell

Plate

Minimum impact values (average of

hardness,

thickness,

two or more test specimens), ft-lb

BHN

inches

Specimen Size

Standard

3/4 width 1/2 width

207

4-12 incl.

65

212

4-12 incl.

63

217

4-12 incl.

61

223

4-12 incl.

59

229

4-12 incl.

57

235

4-12 incl.

55

241

4-12 incl.

53

248

4-12 incl.

50

255

4-12 incl.

47

262

4-12 incl.

44

269

4-12 incl.

40

277

4-12 incl.

37

285

4-12 incl.

33

262

1/4 to less than 4

55

269

1/4 to less than 4

51

277

1/4 to less than 4

47

36

24

285

1/4 to less than 4

43

33

22

293

1/4 to less than 4

39

30

20

302

1/4 to less than 4

35

27

18

311

1/4 to less than 4

31

24

16

321

1/4 to less than 4

28

21

14

331

1/4 to less than 4

25

19

13

341

1/4 to less than 4

22

17

11

352

1/4 to less than 4

19

15

10

363

1/4 to less than 4

17

13

9

375

1/4 to less than 4

16

12

8

388

1/4 to less than 4

16

12

8

1/ ASTM E140 shall be used to convert HRC readings to BHN equivalents.

3.2.10 Workmanship.

3.2.10.1 Surface imperfections. The top and bottom surface of each plate shall be free from the

following surface defects: slivers, laps, checks, seams, blisters, snakes, cold shuts, cracks,

burning, and laminations (see 6.4). The surface of each plate shall be such that mill scale or

oxidation product shall not interfere with determination of acceptability. Imperfections listed

above which are of such nature as to affect the fabrication of the material, are rejectable.

11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |