|

|||

|

Page Title:

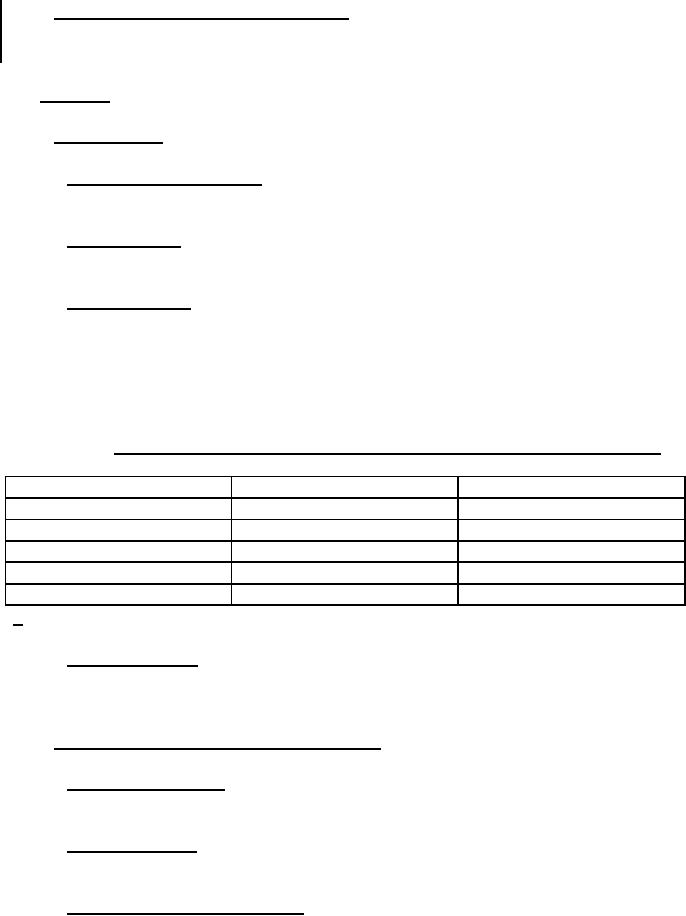

Table VI. Thickness ranges and corresponding test projectiles for first article testinq 1/. |

|

||

| ||||||||||

|

|  MIL-A-46100D (MR)

w/INT. AMENDMENT 2

4.3.1 Separately heat treated ballistic test plate. When the procuring activity allows a

ballistic test plate to be heat treated separately from the production plates it represents, it

shall be so stated in the data (see 6.6).

4.4 Sampling.

4.4.1 For first article.

4.4.1.1 Chemical analysis samples. One sample for chemical analysis shall be taken from

each plate submitted.

4.4.1.2 Impact samples. At least two impact test specimens shall be taken

from each test plate submitted for ballistic testing.

4.4.1.3 Ballistic samples. Two ballistic test plates of the same ordered thickness for each

nominal thickness range shown in table VI below shall be submitted for ballistic testing and

shall represent any other thickness in the range. One sample shall be taken from the first

plate heat treated and one from the last plate heat treated in the initial lot produced. When

only one plate is heat treated, a sample shall be taken from each end of the plate. The

ballistic test plates shall be 12 inches by 36 inches.

TABLE VI. Thickness ranges and corresponding test projectiles for first article testinq 1/.

Nominal thickness range, in

Obliquity, degrees

Test Projectile

0.125 to 0.300 incl.

30

Cal .30 AP, M2

0.301 to 0.590 incl.

30

Cal .50 AP, M2

0.591 to 0.765 incl.

30

14.5 mm API, B32

0.766 to 1.065 incl.

30

14.5 mm API, BS41

1.066 to 2.000 incl.

0

20 mm API-T, M602

1/ Minimum required ballistic limits are tabulated in tables VII through X of the Appendix.

4.4.1.4 Bend test samples. Unless otherwise specified (see 6.2), two samples shall be taken

from each submitted test plate and shall be tested in accordance with 4.6.4 and shall meet

the requirements of 3.2.5.

4.4.2 Sampling for quality conformance inspection.

4.4.2.1 For chemical analysis. At least one sample for chemical analysis shall be taken from

each heat in accordance with the applicable method specified in ASTM A751 (see 6.5).

4.4.2.2 For hardness tests. The Brinell hardness of each plate, as heat treated, shall be

measured in two places, one at each end of a diagonal on one surface of the plate.

4.4.2.3 For Charpy V-notch impact tests. A sample shall be taken from a plate representing

each lot for Charpy V-notch impact tests. The sample shall be the same thickness as the

11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |