|

|||

|

|

|||

|

Page Title:

|

|

||

| ||||||||||

|

|  MIL-B-52734C (ME)

Minor

201.

Warning and instruction signs, decals and stencilling missing (see

3.1.1, 3.11 and 3.12).

202.

Lubrication and lubrication fittings not as specified (see 3.9).

203.

Treatment and painting not as specified (see 3.10).

204.

Identification marking and hose assembly identification missing or

incorrect (see 3.11).

4.5.2

Tests.

4.5.2.1 Test conditions. All tests, with the exception of the operational

performance test and the reliability test, shall be conducted at an ambient

air temperature of from plus 25 F to plus 100 F with the hydraulic oil

temperature between plus 25 F and plus 90 F. The operational performance

and reliability tests may be conducted at existing ambient temperatures,

except that the contractor shall be responsible for ensuring that icing

conditions do not impair performance of the operational test. Hydraulic oil

conforming to MIL-L-2104, Grade 10, shall be used for all tests. Prior to

assembly of hydraulic components for test or installation into bridge bays,

all hydraulic lines and hydraulic components shall be free of any foreign

matter, such as metal chips and filings, that may in any way contaminate the

oil or damage the system. All equipment shall be operated in accordance with

the applicable technical manual.

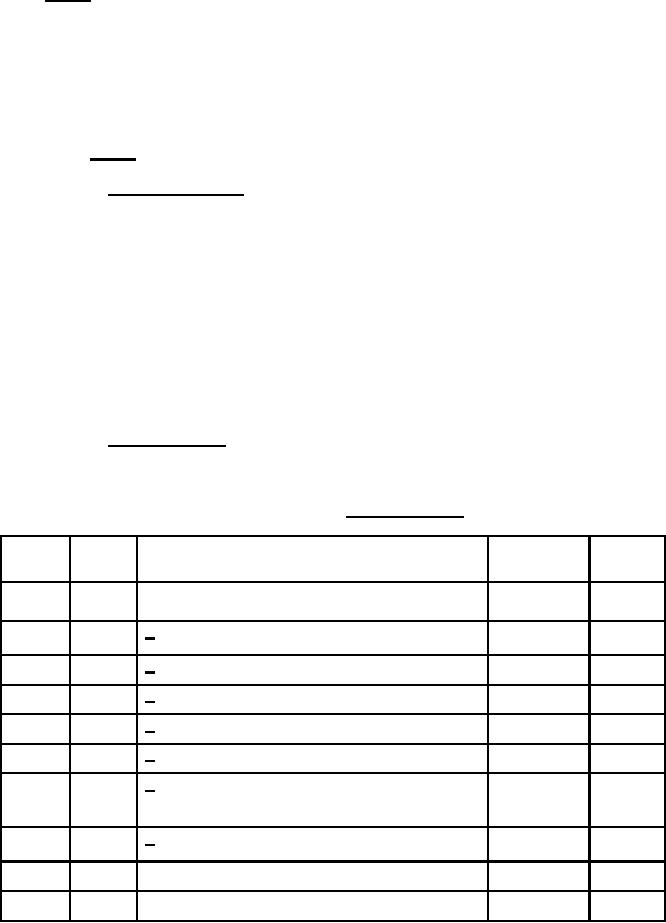

4.5.2.2 Test schedule. All tests shall be conducted in accordance with

table II and in the specified sequence.

TABLE II.

Test schedule.

First

Qual.

Test

Test

Reqmt.

Art.

Conf.

Para.

Para.

X

X

Test conditions

4.5.2.1

X

X

1/ Limbering up of hydraulic cylinder

4.5.2.3

X

X

1/ Hydraulic cylinder pressure

4.5.2.4

3.5.1

X

X

1/ Cylinder relief valve

4.5.2.5

3.5.6

X

X

1/ Control valve

4.5.2.6

3.5.5

X

X

1/ Internal leakage

4.5.2.7

3.5.7

X

X

1/ Ramp articulation system pressure

4.5.2.8

3.5.2,

3.5.3,

3.5.4

X

X

2/ Pull

4.5.2.9

3.15

X

X

Ponton leak

4.5.2.10

3.14

X

X

Operational performance

4.5.2.11

3.8

15

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |