|

|||

|

Page Title:

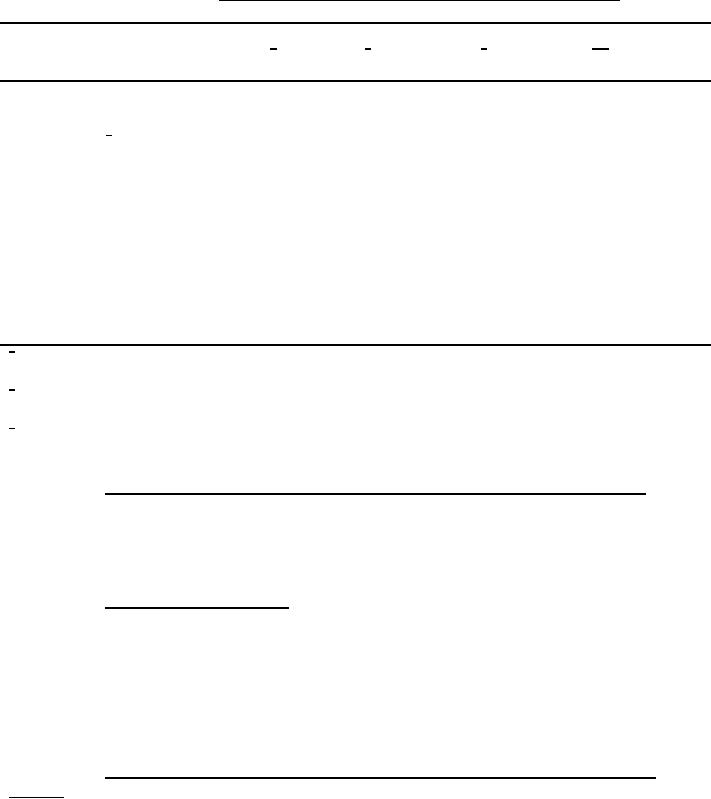

Table II Standard comparison compound formulae |

|

||

| ||||||||||

|

|  MIL-C-10578D

Table II.

Standard comparison compound formulae

1/

1/

1/

1,2/

Materials

Type I

TypeII

Type III

Type IV

Type V

Phosphoric acid

118 mL

35 mL

85 mL

118 mL

118 mL

(85%)

3/

Detergent

5 mL

5 mL

--

--

5 mL

Diethyl thiourea

--

--

0.50 g

--

--

Butyl cellosolve

40 mL

62.5 mL

--

40 mL

--

Nacconol NRSF

--

--

2.0 g

--

--

Pluronic L62

--

--

--

5 mL

--

(see 6.4)

Pluronic L64

--

--

--

5 mL

--

(see 6.4)

1/

Water, sufficient to bring total volume to 250 mL, shall be

added

2/

This formula should be aged 3 weeks before using, or diluted,

when first prepared, to 1000 mL for use without further dilution.

3/

Triton X-100, ethoxylated primary or secondary alcohols, or

straight-chain alkyl phenols.

3.3.2 Grease removal (applicable to types I, II, and IV). The

diluted conditioner shall be equal or superior to the standard

comparison formula of the same type (specified in table II)

prepared and tested under the same conditions, in removing greasy

films when tested as specified in 4.3.6.

3.3.3 Inhibiting agents. Types I, II, IV and V shall be

noninhibited and free from agents which will tend to interfere

with the free action of the conditioner on the metal being

treated. Type III shall contain an inhibiting agent so that the

attack on the base metal shall be held to a minimum. The

corrosion removal properties of Type III compound shall not be

impaired by the presence of the inhibiting agent. The compound

shall be tested as specified in 4.3.7.

3.3.4 Etching action (applicable to types I, II, IV and V

only). The diluted metal conditioner shall produce no more than

a slight etching action when allowed to remain in contact with

iron, galvanized iron, brass or aluminum at a temperature of 77

9F (25 5C). The etching action shall be essentially equal to

that produced by the standard comparison compound (see table II)

of the same type, when tested as specified in 4.3.8.

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |