|

|||

|

Page Title:

Table II Electric motor ratings |

|

||

| ||||||||||

|

|  MI-L-C-13874K

compressor to be lifted in the normal operating position. The provisions shall be

located so that not less than l-inch clearance is maintained between slings and

all exterior parts and shall be fastened to members which will withstand stresses

in the amount and direction of pull specified for the provisions without weld

failure, permanent deformation, cracking, loosening, or breaking of the provision

o r i t s c o n n e c t i n g s t r u c t u r a l c o m p o n e n t s . S l i n g i n g provisions may also be used as

tiedown provisions when such provisions meet the requirements specified in

3.19.2.1.

L i f t points shall be labelled "LIFT HERE". T h e l a b e l s s h a l l c o n f o r m t o

t h e requirements of MIL-STD-1472.

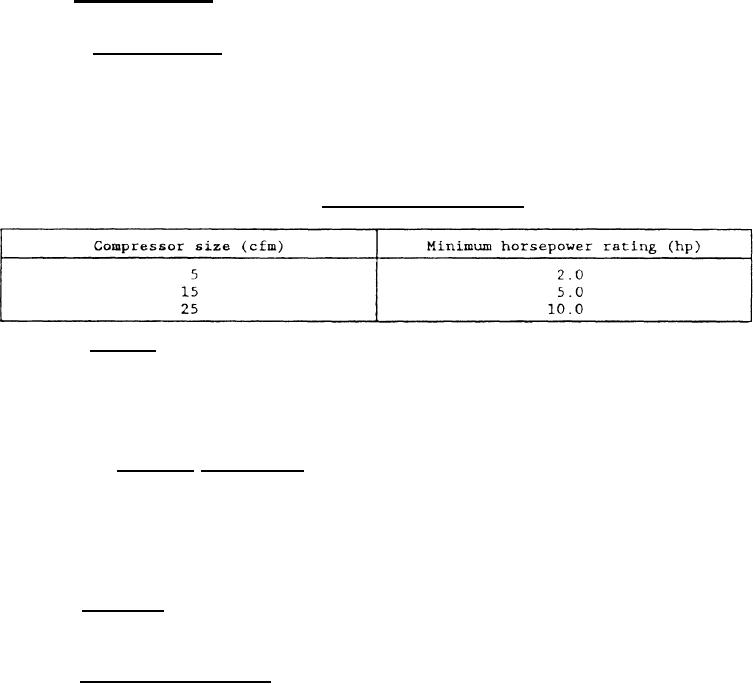

3 . 2 0 E l e c t r i c - m o t o r s . M o t o r wiring and control systems shall conform to the

p r o v i s i o n s of ANSI B15.1.

Electric motor. Unless otherwise specified (see 6.2), each compressor

3.20.1

shall be driven by a single phase, induction, squirrel cage, electric motor,

c a p a c i t o r (drip proof) conforming to NEMA MG-1. T h e e l e c t r i c m o t o r s h a l l h a v e t h e

c o n t i n u o u s h o r s e p o w e r r a t i n g a s s p e c i f i e d i n t a b l e I I T h e horsepower required by

t h e compressor when performing at 200 psig shall be not more than the continuous

h o r s e p o w e r r a t i n g , i n c l u d i n g t h e s e r v i c e f a c t o r , o f t h e m o t o r . T h e motor shall

have all electrical equipment connected for operating on a power supply having the

characteristics as specified (see 6.2) .

TABLE II

Electric motor ratings.

3.20.2 Starter.

A starter shall be furnished conforming to MIL-S-12514, type

I , c l a s s 2 , a n d shall be provided with a NEMA type 12 (dripproof) and dust tight

enclosure . T h e c l a s s 2 s t a r t e r s h a l l b e m a g n e t i c a l l y o p e r a t e d b y a p r e s s u r e

switch tch

The starter shall be reset by an externally operable switch mounted in

motor starter enclosure. The maintained contact stop-start switch and reset shall

be located in an accessible location.

3 . 2 0 . 2 . 1 L o w - v o l t a g e protection.

A low-voltage protective device shall be

provided to open all ungrounded line conductors whenever voltage falls or drops

below a predetermined level or after the operation of the overload protective

device. After the operation of the overload protective device, the reset switch

s h a l l r e q u i r e a c t u a t i o n b e f o r e t h e m o t o r c a n b e r e s t a r t e d . T h e overload

p r o t e c t i v e d e v i c e s h a l l b e r e m o v a b l e a n d r e p l a c e a b l e . T h e holding coil may be

regarded as the low-voltage protective device.

3 . 2 0 . 3 C o n d u i t W i r i n g shall be installed in conduit conforming to WW-C-566,

U L 6, UL 514, or UL 1242, as applicable. C o n d u i t o u t l e t s s h a l l c o n f o r m t o

W-C-586.

3 . 2 0 . 4 P r e s s u r e r e g u l a t i o n . Each compressor shall have an adjustable,

p r e s s u r e - a c t u a t e d e l e c t r i c c o n t r o l . The control shall be adjusted to stop the

m o t o r when the pressure has risen to 200 +0, -10 psig, a n d to start the motor when

10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |