|

|||

|

Page Title:

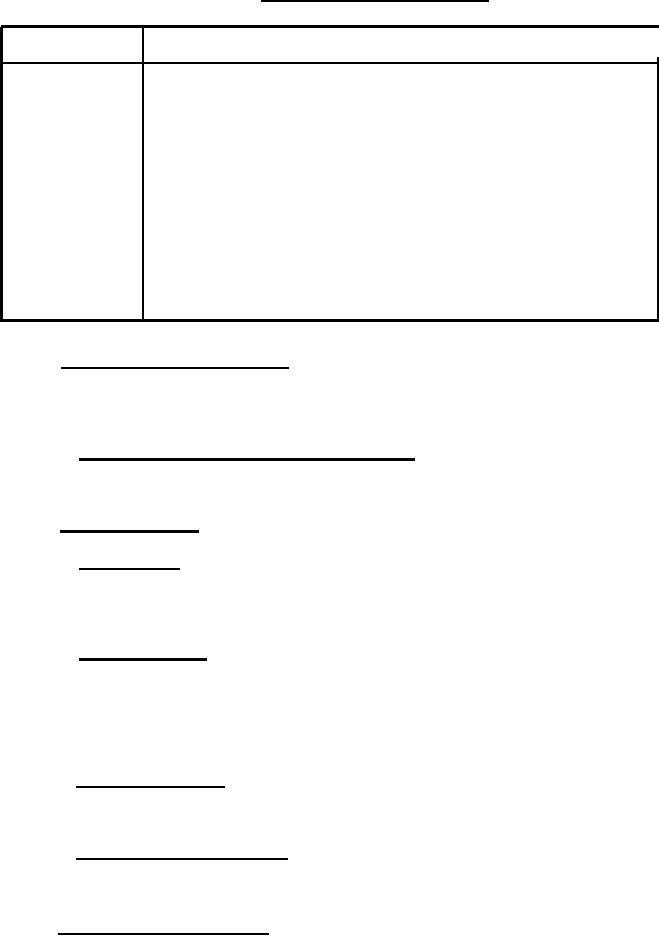

Table I. Classification of defects |

|

||

| ||||||||||

|

|  MIL-C-24224B ( SH)

TABLE I.

Classification of defects.

Defects

Categories

Critical:

None defined.

Major:

Material not as specified.

101

Parts missing, damaged, defective, foreign matter

102

present, irregularities or malfunctioning.

Assembly of parts not as specified.

103

Threading not as specified.

104

Protective coating not as specified.

105

Weight not as specified.

106

Dimensions not as specified.

107

Marking not as specified.

108

4.4 Quality conformance tests. Each of the sample cartridges selected in

accordance with 4.2.3 shall be subjected to the tests of 4.5.1 through 4.5.4.

If any cartridge fails one or more of the tests, the lot represented by the

sample shall be rejected.

4.4.1 Quality conformance inspection report. A quality conformance inspec-

tion report shall be repeated by the contractor and provided in accordance with

the data ordering document (see 6.2.2).

4.5 Test procedures.

4.5.1 Gas leakage. Each fully charged gas pressure cartridge shall be

totally immersed in water conditioned at 115F for a period of not less than

4 hours and examined for C02 leakage. Evidence of leakage shall constitute

failure of this test. Gas cartridges shall be thoroughly dried after the test.

4.5.2 Filling weight. Gas cartridge shall be weighed on a scale graduated

in 1/8 ounce increments with weights being recorded and checked with full weight

stamped on the cartridge. The cartridge seal shall be loosened, allowing the

gas pressure to slowly escape. After all C02 gas has escaped, the cartridge

shall be reweighed to determine the weight of C02 gas which has escaped, thereby

checking the C02 filling against that shown on figure 1.

4.5.3 Safety seal disc. The safety seal disc shall be tested and deter-

mined to rupture between 4,050 and 4,500 pounds per square inch (lb/in*),

internal pressure.

4.5.4 Magnetic test (class 2). Class 2 cartridges shall be subjected to a "

magnetic permeability test using a permeability indicator, low-mu (Go-No-Go) as

specified in MIL-I-17214 to determine conformance with 3.1.

4.6 Inspection of packaging. Preservation , packaging, packing) and marking

shall be inspected to assure compliance with section 5 of this specification.

7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |