|

|||

|

Page Title:

Table III. Military-commercial connections. |

|

||

| ||||||||||

|

|  MIL-C-52128C

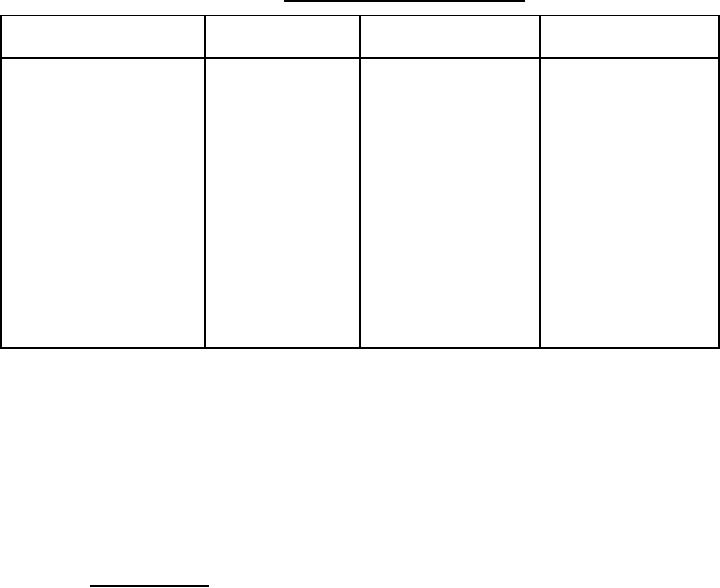

TABLE III. Military-commercial connections.

Mil. Plug

Connection

Comm. TTMA

Function

Terminal

Instructions

Wiring Ident.

-

No.

A

Blackout Marker

YEL (3)

Connect to

B

Ser. Left Turn and Stop

-

No.

C

Blackout Marker

WHT (1)

Connect to

D

Ground

BLK (2)

Connect to

E

Ser. Tail & Marker

BRN (6)

& Connect to

-

No.

F

Blackout Stop

-

No.

H

Blackout Marker

GRN (5)

Connect to

J

Ser. Right Turn and Stop

BLU (7)

No.

K

Aux. Power(Hot)

-

Ground to Frame

L

Ground

-

No.

M

Electric Brake

-

No.

N

Electric Brake

With the military system installed, the TTMA marker circuits, color coded BLK (2) and BRN

(6), shall be electrically isolated from each other, thus preventing 12-volt current cross-over

when operated by commercial trucks through the 12-volt TTMA plug. Replaceable diodes may

be used, having a minimum amperage of 150 percent of the current demand of the running lamps

served. Military circuits letter coded B and J on the tactical trucks are passenger car

combination stop and turn signal type, using the same lamp filament, and there is no single stop

lamp circuit. As a result, the trailer's turn signal lamp circuits, YEL (3) and GRN (5), shall

function as both turn signal lamps and stop lamps and the trailer's normal stop circuit, RED (4),

cannot be energized from the military 24-volt system input.

3.14.7 Stabilizing jacks. The semitrailer shall be equipped with not less than four

screw-action stabilizing jacks permanently attached to the chassis. The jacks shall conform to

GGG-J-51, Type I, Class 3, rated capacity 15 tons, except that the diameter of the screw shall be

not less than 2-1/2 inches. The jacks shall have steel ball-bearing caps. Detachable pads shall be

furnished. Each jack pad shall have sufficient area to reduce ground pressure to less than

100 psi. Provisions shall be made for stowing the pads in the toolbox. The stabilizing jacks shall

fold and be secured for travel. The two front stabilizing jacks shall also serve as landing gear

and support the front of the crusher when there is nothing under the upper fifth wheel. The

stabilizing jacks shall be located so as to stabilize the crusher when the crusher frame is level,

dolly is installed under upper fifth wheel, and all wheels are blocked up clear of the ground.

Two 20-ton hydraulic jacks shall be furnished to raise and lower the crusher as required for

coupling and uncoupling the dolly or truck-tractor. The hydraulic jacks shall conform to

GGG-J-51, Type VII, Class 2, Style B. The hydraulic jacks shall be stored in the toolbox. When

specified, the jacks will be furnished to the contractor by the Government.

24

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |