|

|||

|

Page Title:

Quality conformance conditions and controls. |

|

||

| ||||||||||

|

|  MIL-C-63550E(AR)

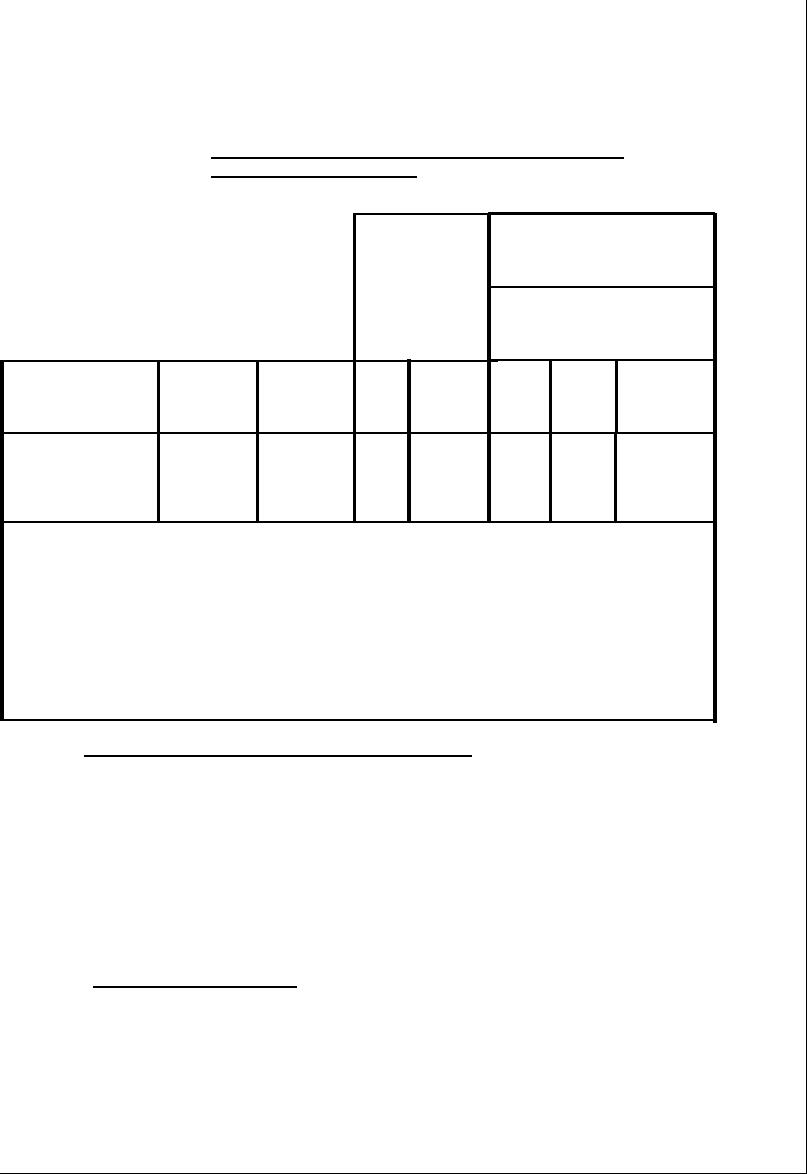

TABLE III.

Preproduction, initial production, and quality

conformance inspections. - Continued

Quality confor-

mance inspection

Special

Classification of

tests and

characteristics

examinations

Pre-

Initial

Crit-

Require-

Minor

prod

ical

Major

prod

Description

ment

Method

4.0

Workmanship

x

x

4.3.5

3.3.5

4.0

Packaging

4.4

x

5.

Note:

Assemblies manufactured using harness wiring boards or equivalent

equipment may be sample inspected once the wiring board has been cer-

tified acceptable to produce assemblies of the required dimensional

and angular configuration.

The rejection of one assembly of a sample shall be cause for 100 per-

cent inspection of the remaining assemblies of the lot, and sampling

of subsequent lots shall not be permitted until the wiring board has

been corrected and rectified.

4.1.3 Quality conformance conditions and controls. Quality conformance

inspection shall consist of the examinations and tests specified in table III

as indicated by the existence of an acceptable quality level (AQL) or fre-

quency of inspection number in one of the classification of characteristics

columns. Examples of the number to be used are: 100% and 1.5. Quality

formance inspection shall be performed in accordance with the methods speci-

fied in 4.2.

Note:

100% means each unit produced shall be inspected

for the indicated characteristics (see 4.1.3.1.2).

1.5 signifies an AQL number and indicates the char-

acteristic may be sample-inspected (see 4.1.3.1.1).

4.1.3.1 Lot-by-lot inspection. Lot-by-lot inspection shall consist of

sampling and acceptance (100 percent) inspection as specified in table III.

An inspection lot shall consist of all assemblies of one type, submitted at

one time for quality conformance inspection.

22

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |