|

|||

|

|

|||

| ||||||||||

|

|  MIL-C-82629(OS)

3.7 Mechanical requirements. The cable assembly shall successfully meet the following mechanical

requirements:

3.7.1 Mating or unmating force. The tube door plug shall fully engage or disengage with an axial

force of not more than 60 pounds (267 N). See 6.3.

3.7.2 Cable strength. The cable assembly shall withstand a 200-pound (890-N) load applied in

accordance with 4.5.3 without functional failure,

3.7.3 Cable flexibility. The cable assembly shall withstand the torsion and low temperature

bending specified in 4.5.4 without functional failure.

3.8 Electrical requirements. The cable assembly shall successfully meet the following electrical

requirements:

3.8.1 Dielectric strength. The cable assembly shall withstand, without arcing, a 5-second appli-

cation of 1000 volts as to any conductor with all adjacent conductors and shields at ground potential.

3.8.2 Insulation resistance. The insulation resistance between any conductor or shield of the

cable assembly and all others connected in parallel shall be greater than 70 megohms when measured

with a potential of 500-750 vdc.

3.8.3 Continuity. The cable assembly shall maintain continuity between each pair of corresponding

connector plug and tube door plug contacts.

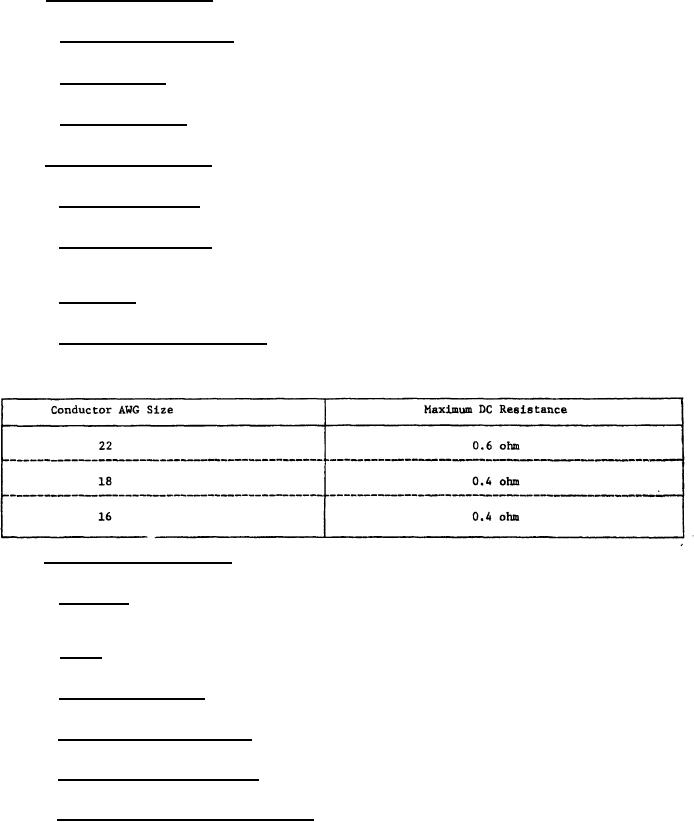

The maximum resistance of each circuit shall be as shown in

3.8.4 Contact, conductor resistance.

Table 1.

TABLE I.

CIRCUIT RESISTANCE

3.9 Environmental requirements. The cable assembly shall be capable of meeting the other re-

quirements herein during or after being subjected to the following environmental conditions.

3.9.1 Vibration. The cable assembly shall successfully withstand a vibration test in accordance .

with MIL-STD-167, Type I. During this vibration there shall be no circuit discontinuities exceeding

100 microseconds in duration.

3.9.2 Shock. The cable assembly, mounted to simulate service installation, shell withstand the

shock tests of MIL-S-901 for lightweight equipment.

3.9.3 Salt water immersion. The cable assembly, with connector attached, shall successfully

withstand immersion in salt water for 30 16-hour periods with 8 hours between immersions.

The cable assembly shall withstand exposure to 23" F (-5 C)

3.9.4 Low temperature (operating).

for 48 hours.

The cable assembly shall withstand exposure to 135 F (57 C)

3.9.5 High temperature (operating).

for 48 hours.

3.9.6 Temperature and humidity (operating).

The cable assembly shall withstand the temperature

and humidity (operating) test of 4.5.6.6.

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |