|

|||

|

Page Title:

Table III. Quality conformance test sequence. |

|

||

| ||||||||||

|

|  MIL-C-82632A(OS)

4.2.2 Quality conformance sample

4.2.2.1 Inspection lot. An Inspection lot for quality conformance inspection

shall consist of 30 each of the connecters and parts which are part of a homogen-

eous production and are submitted to the designated inspection activity. Homogen-

eous production is difined as those parts (housings) manufactured from a given set

of core pins. Should the core pins have to be replaced, this constitutes the end

of one homogeneous production and the start of another homogeneous production.

4.2.2.2 Sampling Connector and part sampling shall be in'accordance with

MIL-STD-105, Inspection Level II. The acceptable quality level (AQL) for

connectors and parts shall be 1.0 for major characteristics and 2.5 for minor

characteristics or as otherwise indicated on component drawings. The total

housing samples shall consist, as near as possible, of an equal number of

housings from each mold cavity.

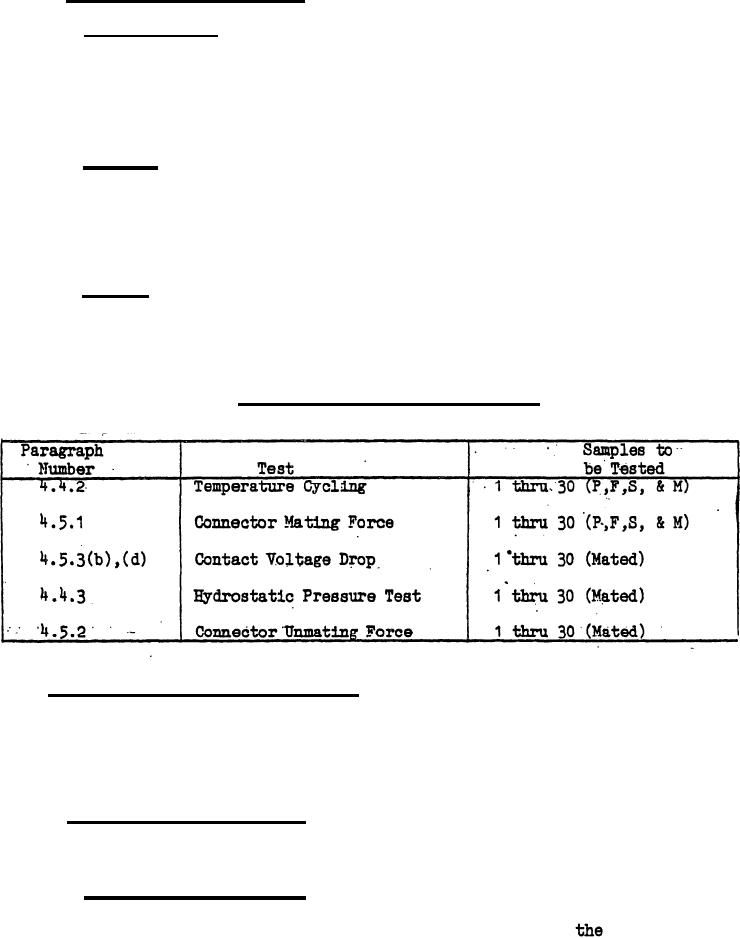

4.2.2.3 Testing. The quality conformance sample shall be subjected to the

tests of Table III in the sequence listed. When specified in the contract or pur-

chase order, certified inspection data covering the results of quality conformance

inspection and tests shall be forwarded to the procuring activity.

TABLE III Quality conformance test sequence.

4.3 Examination of physical attributes. Each connector and part sampled shall

be examined to verify that the materials, design, construction, physical dimen-

sions (with the exception of hardness tests and those dimensions on the male and

female housings listed an the applicable Governmaut drawings as a "Major Classif-

ication of Characteristics") configurations, markings, and workmanship are In

accordance with 3.3.1, 3.3.2, 3.3.3, 3.4.2 and 3.6.

4.3.1 Housing sample disposition. First article samples 31 through 45 (F & M),

which have successfully passed the inspection procedures of 4.3, shall be

subjected to the following test:

4.3.1.1 Dimensional measurements. Those dtiensions listed as a "Major Classif-

cation of Characteristics" on the applicable Government drawings shall be examined

on the male and female housings to verify that the housings meet

requirements

of 3.3.2 (destruction of the housings will be necessary).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |