|

|||

|

|

|||

| ||||||||||

|

|  MIL-D-70436(AR)

contents shall be dried in an oven maintained at 60 degrees C plus

or minus 5 degrees C for 30 minutes, cooled in a desiccator and

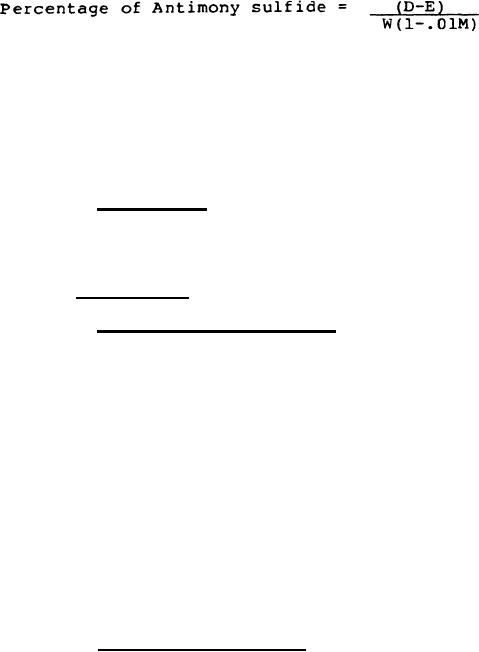

weighed. The loss in weight shall be calculated as the percentage

of tetracene in the sample on a dry basis as follows:

where:

D = Weight of crucible and sample after treating with hot

water.

E = Weight of crucible.

W = Weight of sample.

M = Moisture content of sample obtained in 4.5.3 in percent.

4.5.5.5 Lead azide. The lead azide content in the sample of

a dry basis, shall be determined by subtracting from 100 the

combined percentages of barium nitrate, lead styphnate, tetracene

and antimony sulfide.

4.5.6 Functioning.

4.5.6.1 Sensivitity and output. The sample detonators shall

be randomly selected from each lot. The detonator shall be

assembled with lead 11834335 in accordance with drawing 11834340.

A weight of 0.25 ounce plus or minus 0.01 ounce shall be dropped

on the firing pin, to function the detonator, from a height of

five (5) inches maximum. The height of drop shall be measured as

the height from the top of the firing pin to the bottom of the

weight. A detonator that fails to fire shall be classed

defective. A detonator that fires but fails to initiate the lead

sufficiently to produce a dent in the steel witness block of the

required depth shall be classed defect if the detonator

confinement sleeve expansion is 0.330 inch diameter or greater.

If the confinement sleeve expansion is less than 0.330 inch

diameter, the detonator shall not be classed defective, but the

detonator classed defective and the result of a no-test. The

indentation depth shall be measured using a probe with a 0.017

inch plus or minus 0.002 inch spherical radius tip.

4.5.6.2 Varicomp initiation. The sample detonators shall be

randomly selected from each lot. The detonator shall be assembled

with test lead 11834345 in accordance with drawing 11834340 and

functioned as in 4.5.6.1. A detonator that fails as specified in

4.5.6.1 shall be classed defective. The indentation depth shall

be measured using the probe specified in 4.5.6.1.

20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |