|

|||

|

Page Title:

Table IV. Quantitative requirements of the enamel.1/ |

|

||

| ||||||||||

|

|  MIL-E-24763A(SH)

w/INT. AMENDMENT 1

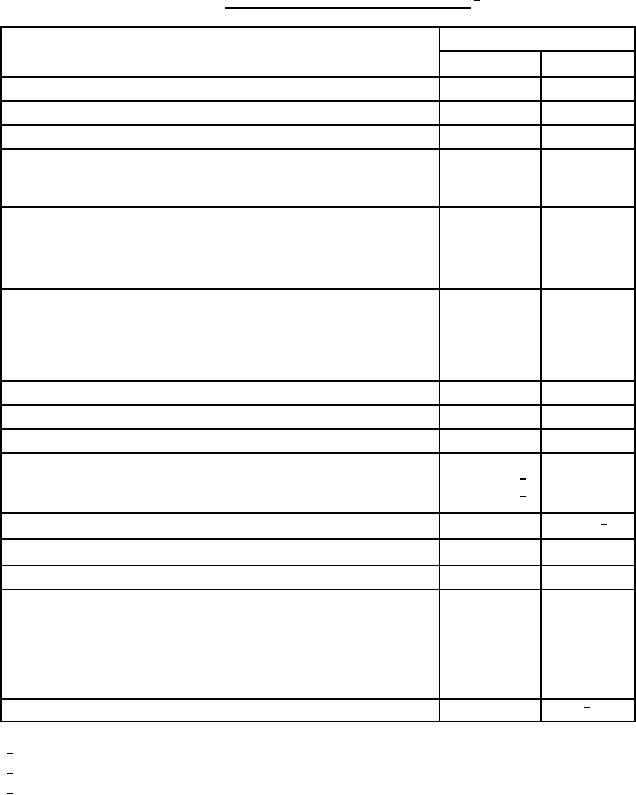

TABLE IV. Quantitative requirements of the enamel.1/

Requirements

Characteristics

Minimum

Maximum

Consistency, Krebs-Stormer, shearing rate, equivalent krebs unit

---

100

Fineness of Grind, Hegman

6

---

Flashpoint, degrees Celcius (C) (Fahrenheit (F))

38 (100)

---

VOC, g/L (Lb/gal)

Type I

---

340 (2.8)

Type II

---

250 (2.1)

Drying time:

Set-to-touch, hours

---

2

Dry through, hours

---

8

Dry-to-recoat

---

16

Gloss (60-degree specular)

Class 1

85

---

Class 2

45

60

Class 3

15

30

Class 4

5

15

Volume Solids, percent , ASTM D2679

35

---

Coarse particles and skins, percent by weight

---

0.2

Flexibility, 1 mil dry film, 0.25-inch mandrel

Pass

---

Impact resistance, 1 mil dry film, 3.6 inch-pounds

No damage1/

---

Direct

No damage1/

---

Reverse

0.0052/

Lead, percent weight by total solids

---

Dry film contrast ratio, percent

0.98

---

Sag resistance, anti-sag index

7

---

Contrast ratio

---

Gray and black colors

0.99

---

0.94

White colors

---

Red, yellow and orange colors

0.93

---

All other colors

0.96

3/

Soluble and total metal content

---

Note:

1/

see 3.8.11

2/

The allowable levels of lead and lead compounds (total) shall be maintained at this level or lower.

3/

See 3.5.

9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |