|

|||

|

|

|||

| ||||||||||

|

|  MIL-E-48441A(MU)

Retain the applied pressure in the elbow assembly for the the duration

specified in 3.8. During this time period, the boresight knobs and the

diopter adjustment shall be rotated to their clockwise and counterclockwise

stops. At the end of this time period there shall be no evidence of

leakage as indicated on the pressure gage of the-testing equipment, to

determine compliance with 3.8. Upon satisfactory completion of the

sealing test, the elbow assembly shall then be flushed with the dry

nitrogen gas specified herein. The interior atmosphere of the elbow

assembly shall be periodically sampled through the dew point tester

until the atmosphere shows a dew point at least as low as minus 25

degrees Fahrenheit. When this atmosphere is attained within the elbow

assembly, the elbow assembly shall conform to the requirement of 3.8.

NOTE: The Battery Ground Cap 11733479 and Cap 10515991 shall be re

moved from the elbow assembly during the sealing test.

4.6.9 Reliability demonstration test.- A reliability demonstration

test shall be conducted as part of first article test to assure compliance

with the requirement of paragraph 3.9 at a 70% confidence level. A

minimum of 25 hours on each sample elbow assembly (sample size 3) shall

be accumulated after/during exposure to each nonoperating/environment of

this specification. Additional hours are required at 75 15F in order

to accumulate a minimum of 800 hours on each sample. The sample elbow

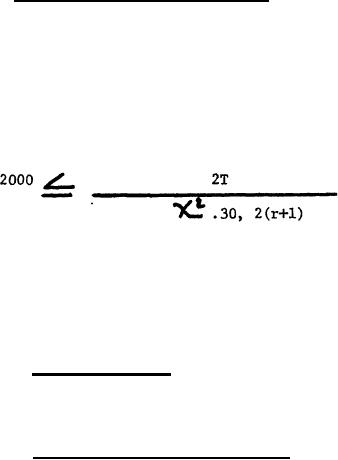

assembly shall be tested until the total operating time (2408 hours

minimum) satisfies the following relationship or until 6 failures have

occurred or 14,000 hours (maximum) have been accomplished

T = Total test hours

XZ. 30, 2 (r+l) = Chi Square lower 70% confidence level with

2(r+l) degrees of freedom

r = Number of chargeable failures,

4.6.9.1 Reliability data.- Data collected will consist of all

equipment malfunctions, number of hour-s completed when these malfunctions

occurred, nature and cause of malfunction, time required to correct

malfunction, and required corrective action.

4.6.9.2 Reliability failure definition.- Any malfunction which

renders the elbow assembly inoperative or operative outside the limits

of this specification. In determination of chargeable failure, the

following clarification shall apply:

a. If, upon failure, analysis (to determine the cause of mal-

function), an assignable cause (related to manufacturing process, procedure,

basic design weakness, etc.) is determined as the basis of the malfunction,

the malfunction will not be chargeable as a reliability failure; however,

27

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |