|

|||

|

|

|||

| ||||||||||

|

|  MIL-E-82886(OS)

materials, this chemical analysis must be conducted at least every 6 months on lots of materials being

used. The weight percent of each ingredient shall be to two significant figures.

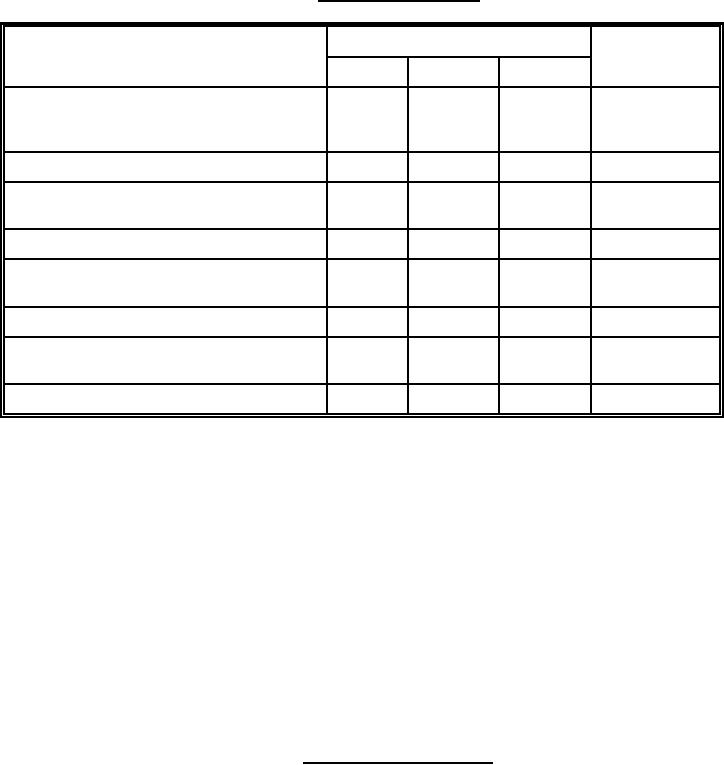

TABLE I. PBXN-109 formulation.

Percent (by weight)

Ingredients

Specification

Nominal

Minimum

Maximum

Sym-Cyclotrimethylene trinitramine (RDX) 1

Type II Class 1

64.00

56.5

65.5

MIL-R-398

Type II Class 5

0.00

0.0

7.0

MIL-R-398

Aluminum Powder, Spherical, Type IV

20.00

18.00

22.00

WS 23150

Polybutadiene, Liquid, Hydroxyl-Terminated,

7.346

7.0

7.5

WS 23148

Type II (PolyBD) 2

Di (2-ethylhexyl) adipate (DOA)

7.346

7.0

7.5

DOD-D-23443

2,2'-methylenebis (4-methyl-6-tertiarybutyl

0.10

0.09

0.11

WS 23151

Phenol) antioxidant

N, N 2-Hydroxyethyl dimethyl-hydantoin (DHE)2

0.26

0.25

0.27

WS 23149

Triphenylbismuth (TPB) 3 (Dibutyltin dilaurate

0.02

0.015

0.045

MIL-T-82825

(DBTL)) 4

(DOD-D-82727)

Isophorone Diisocyanate (IPDI) 2

0.9465

--

--

WS 16305

1

A maximum of 7 percent Class 5 RDX may be used in the formulation to improve processing characteristics.

Addition of Class 5 RDX shall be made at the expense of Class 1 RDX. The total RDX weight shall be between 62

and 66 percent, with a nominal weight of 64 percent.

2

Typical equivalent analyses of binder components used to establish nominal composition are as follows:

PolyBD = 0.82 milliequivalent weight per gram (meq/g) (hydroxyl value) or 1219.5 g/eq (equivalent weight),

IPDI = 113.47 meq/g (equivalent weight),

DHE = 500 mg KOH/g (hydroxyl number) or 112.2 g/eq (equivalent weight),

NCO/OH Ratio = 1.0/1 (nominal).

3

Triphenylbismuth (TPB) is the recommended catalyst. Recommended nominal value is 0.02%.

4

Dibutyltin dilaurate (DBTL) may be substituted for TPB using between 0.002% and 0.02%. However, TPB is the

recommended catalyst.

3.4 Cured explosive requirements (M102). The cured explosive shall meet the requirements specified in Table

II.

TABLE II. Cured explosive requirements.

4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |