|

|||

|

Page Title:

Media migration and vibration tests. |

|

||

| ||||||||||

|

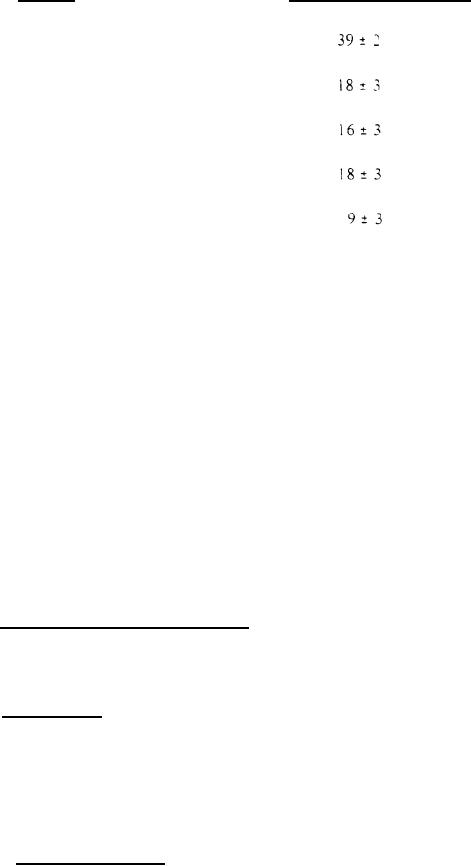

|  MIL-F-27656C(USAF)

Size of Particle

(Micron)

Percent by Weight of Total

0 to 5

10 to 20

20 to 40

Over 40

e. TwO minutes after each dust addition, pressure differential, flow and temperature shall be

recorded For element No. 2 (see paragraph 4.4.3), AC fine test dust shall be added until 40 grams of

dust have been added. For element No. 3 (see paragraph 4.4.3), 200 grams of carbonyl iron E shall be

added. The differential pressure across the filter unit in each test shall not exceed 115 psi. The pump

shall not be stopped during any test. Then, for both element No. 2 and No. 3, additional AC fine test

dust, carbonyl iron E ( 1-12 micron) and glass beads shall be added m equal proportions until a differential

pressure of 5,000 psi is obtained across the element. The dirt capacity of 5.000 psi shall be recorded. The

effluent shall be sampled and tested m accordance with paragraph 4.6.6.3a and b as the differential

reaches 100, 150, 1000, 2000, 3000 and 5000 psi. The samples collected at 100 and 150 psi differential

shall show a maximum particle size of 5 microns. The samples collected at 1000-, 2000-, 3000- and

5000-psi differential shall show a maximum particle size of 18 microns.

f.

Cleanable elements shall be loaded 10 tries to then rated differential pressure and cleaned

10 times. After the final cleaning, the dirt-holding capacity shall be not less than 90 percent of the

original dirt-holdmg capacity at the elements rated differential pressure. Elements shall be cleaned by

chemicals and ultrasonic equipment in accordance with recommendations submitted by the manufacturer.

Cleanable elements shall be subjected to the test specified in 4.6.6.1.

g.

4.6.6.5 Media migration and vibration tests. The filter unit shall be mounted on a test stand and the oil

in the test system shall be precleaned using the procedure specified in paragraph 4.6.6.2.1 The filter

unit. filled to the top of the element with fluid, shall be maintained at 160F for 72 hours.

4.6.5.1 Vibration test. The filter unit shall be cooled to room temperature (70 F to 90 F) and vibrated

in three mutually perpendicular planes. The frequency of vibration shall be varied from 50 to 500 Hz.

with one pass of scanning to be at least 15 minutes, at an acceleration of 10g m each plane with any

resonating frequencies noted. The filter unit shall be vibrated for 1 hour at each of these resonating

frequencies. If no resonance is encountered, the vibrating frequency shall be 500 Hz for 1 hour at an

acceleration of 10g in each plane. The differential pressure indicator shall not actuate during this test.

4.6.6.5.2 Media migration test. At the completion of the vibration period and with the test pumping

system and valves preset to give rated flow through the filter, the system shall be started and 1 gallon

of fluid passed through the filter and effluent collected. The sample effluent shall be completely

filtered through type AA Millipore paper (47-mm disk) and the amount collected and scanned under a

24

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |