|

|||

|

|

|||

| ||||||||||

|

|  MIL-F-5577B

3.5 Design and construction. The fittings

which are riot specifically designate herein

shall be designed and constructed in accordance

and which are necessary for the execution of

with the applicable MS standards and specifi-

this specification shall be selected in accord-

cations in conjunction with the fluid tank and

ance with ANA Bulletin No. 143, except as pro-

component parts to insure that fluid leakage

vided in the following paragraph.

from the fitting shall not occur during normal

3.3.1 MS Standard parts. MS Standard

service life. Class A fittings shall conform

parts shall be used wherever they are suitable

to Standard MS33595, MS33596, MS29550

for the purpose, and shall be identified on the

through MS29557, and MS29572 through

drawing by their part numbers

MS29582, as applicable. The assembly, con-

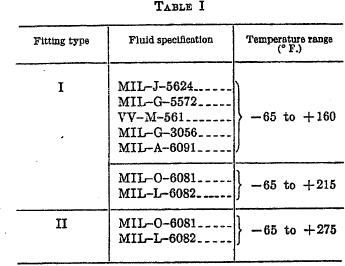

3.4 Materials. All materials used in the

sisting of the cell fitting and attaching parts,

tank fittings shall be sufficiently resistant to

shall be of the necessary strength to provide

fluids listed in table I, to assure satisfactory

adequately for the stresses caused by the

performance throughout the specified tempera-

following:

ture range.

(a) Flexing resulting from vibration.

(b) Impact loads incident to takeoff,

taxiing, and landing (including

catapulting and arresting, where

applicable).

(c) Hydraulic surge of fluid incident to all

dynamic conditions of flight.

(d) Hydraulic surge of fluid incident to

gunfire, where applicable.

(e) Pressure loads resulting from a hydro-

static head of fluid during level flight

or maneuvers, plus resulting differen-

tial venting pressure, or resulting

from any neutral gases used to pres-

surize the cells.

(f) The fitting assembly shall be designed

3.4.1 Fungusproof. Materials that are nu-

in conjunction with the containing

trients for fungi shall not be used where it is

structure to avoid concentration of ex-

practicable to avoid them. Where used and

ternal loads on the fitting assembly or

not hermetically sealed, they shall be treated

fluid tank.

with a fungicidal agent acceptable to the pro-

3.5.1 Through-bolt fittings. Through-bolt

curing activity.

fittings may be utilized only in connections

3.4.2 Metals. Metals shall be of the corros-

where no seal around the bolt is required to pre-

ion-resistant type or suitably treated to resist

vent fluid leakage.

corrosion from fuels, oils, salt spray, and at-

3.6 Class A fittings.

mospheric conditions likely to be met in stor-

3.6.1 Sealing surface (class A). The thick-

age and normal service. Magnesium shall not

ness of the molded sealing surface of the fitting

be used in the construction of these fittings.

and the total thickness variation at the sealing

3.4.2.1 Dissimilar metals. When practi-

surf ace shall be as specified on the applicable

cable, dissimilar metals shall not be used in in-

MS standard.

timate contact with each other.

3.6.2 Sealing-surface flatness (class A).

3.4.2.2 Castings. All metallic castings used

When a transparent acrylic plate of l-inch min-

in tank-fitting assemblies shall be so fabricated

imum thickness is placed on the surface, and

that the tank fluid cannot permeate the casting

the bolts torqued to 60 percent of the nominal

and permit fluid leakage. If necessary to pre-

installation torque, 75 percent of the sealing-

vent porosity, parts shall be treated in accord-

surface width shall be in contact with the plate.

ance with Standard MIL-STD-276.

The plate shall be flat to within 0.0005 inch

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |