|

|||

|

Page Title:

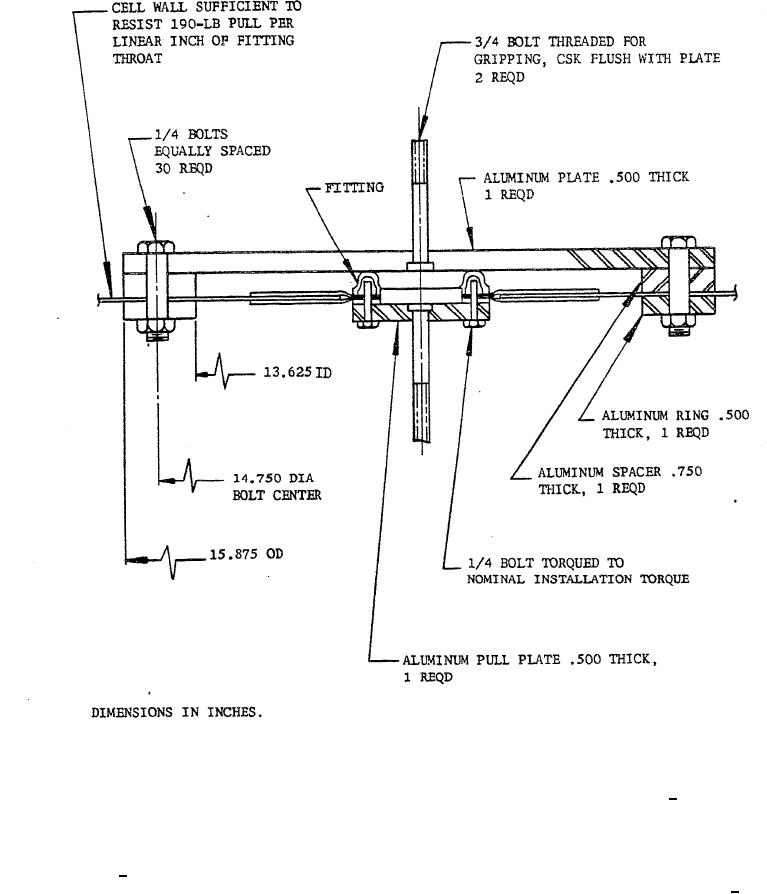

Figure 2. Fitting pullout test setup. |

|

||

| ||||||||||

|

|  MIL-F-5577B

FIGURE 2. Fitting pullout test setup.

ance shall be determined in accordance with

be removed from the oil, wiped dry,allowed to

ASTM Method D1149-55T. The test speci-

stand in fresh oil at room temperature for 4

mens shall consist of strips 0.075 + .005 by 1.0

hours, and the physical properties listed in

by 6.0 inches stretched 10 percent longitud-

table V shall be determined.

nally and held in this condition for the dura-

4.5.2.4 Types I and II fitting rubber stocks

tion of the test. The samples shall not crack

shall be subjected to a 7-day Geer oven cycle at

when exposed to an ozone concentration of 50

158 + 2 F. After cooling for at least 16 hours

parts per 100 million for 30 minutes at 100 + 2

in air, the physical proper-ties listed in table VI

F. A 7-power magnifying glass shall be used

shall be determined.

to examine the samples.

4.5.2.5 Ozone resistance. The ozone resist-

10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |