|

|||

|

|

|||

| ||||||||||

|

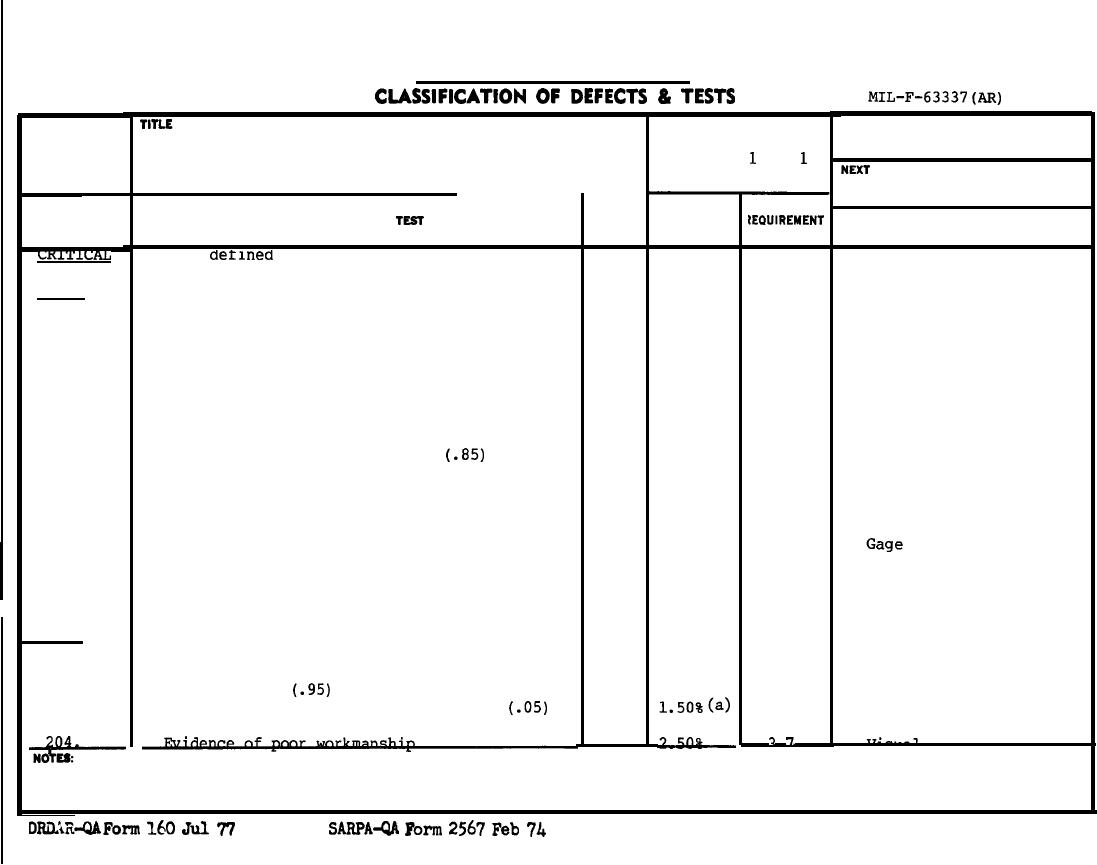

|  QUALITY CONFORMANCE INSPECTION

DRAWING NUMBER

PARAGRAPH

4.4.2.1

Chamber

D 9326857

SHEET

OF

HIGHER ASSEMBLY

F 9324931

AQL

NO. OF

PARAGRAPH REFERENCE

OR

SAMPLE

EXAMINATION OR

CATEGORY

100%

/INSPECTION METHOD

UNITS

PARAGRAPH

None

MAJOR

101.

Salt Spray test

4.5.2

3.2

4.5.2

102.

Diameter of smallest hole in center

0.65%(a)

3.2

Gage

103.

Total length

0.65%(a)

3.2

Gage

104.

0.65%(a)

3.2

Gage

Outside diameter between fins (6 places)

105.

Thickness of fins (12)

3.2

0.65%(a)

Gage

106.

Spacing of fins (12)

0.65%(a)

3.2

Gage

107.

Diameter of rod spacer holes, min (3)

3.2

0.65%(a)

Gage

108.

Diameter above rod spacer hole

(3)

Gage

0.65%(a)

3.2

109.

True position of rod spacer holes

0.65% (a)

3.2

Gage

110.

Diameter of large inside cavity for

0.65%(a)

specified depth

3.2

Gage

111.

Perpendicularity of large inside cavity

0.65%(a)

with specified surface

3.2

112.

Depth to bottom of large cavity to

start of taper

0.65%(a)

3.2

Gage

113.

Internal (32) finish improper

0.65%(a)

3.2

Gage/Visual

MINOR

201.

Distance between forward face and rod spacer

1.50%(a)

hole surface

3.2

Gage

202.

Inside radius around the edge missing

3.2

Visual

203.

External finish improper

1.50%(a)

Visual/Measure

3.2

(a) See 4.5.1 for alternate inspection procedure for cast parts.

Replaces

Which is Obsolete

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |