|

|||

|

Page Title:

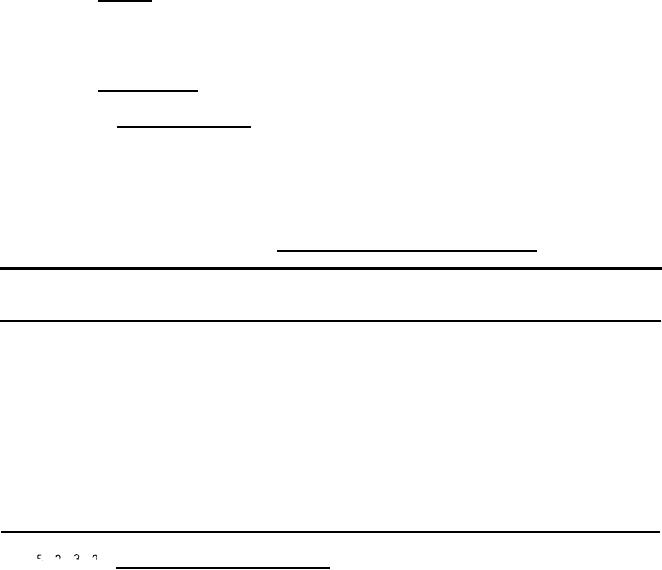

Table I Operating flows and pressures. |

|

||

| ||||||||||

|

|  MIL-H-12732E

4 .5.2.2 Torque. The hypochlorinator shall be disconnected from the water

meter and the torque required to turn the shaft of the hypchlorinator shall be

determined with a torque wrench. Measured torque greater than 8 inch-ounces

shall constitute failure of this test.

4.5.2.3 Performance.

4.5.2.3.1 Test conditions. The unit shall be connected to test equipment as

shown on figure 1 and tested under the conditions given in table I and in

accordance with the test procedure outlined in 4.5.2.3.2.

Data shall be

One data sheet shall be

recorded on a test data sheet as shown on figure 2.

furnished with each unit. The test equipment shall not be limited to that shown

on figure 1.

Operating flows and pressures.

TABLE I.

Flow rate (gpm)

Discharge pressure (psig)

Condition

350 +8

A1

100

A2

210 +7

100

70 +6

100

A3

70 +5

25

B1

42.7 +3

25

B2

15 --+1

B3

25

15 +1

c1

25

8.5 +0.8

25

C2

2 +0.5

25

C3

-0.0

Test setup shall be as follows:

4. 5.2.3.2

Test setup and procedure.

Connect the unit to a source of tap water capable of delivering not less

a.

than 350 gpm at 125 psig so that the flow enters the inlet end of the

4. inch line and leaves at the outlet end.

Flow rates shall be set with calibrated rotameters, or the discharge

b.

shall be caught in a container of Known volume or weighed if desired.

c.

A single adjustment of the range valve shall be made for each of the

conditions shown in table I.

provide a means of measuring total Waste flow from the diaphragm pump.

d.

Set up a 1,000 cubic centimeter (cc) graduate (divided every 2 cc) as

e.

a solution reservoir and fill with water. Place on a support so that

the water level, when full, is at the same eievation as the liquid

level in the solution container when full.

Do not immerse

Remove suction tubing and attach to botton of graduate.

f.

tubing in an open top graduate.

Adjust the dosage control to maximum setting.

g.

12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |