|

|||

|

Page Title:

Table I - Physical and chemical requirements. |

|

||

| ||||||||||

|

|  MIL-L- 24131C(SH)

3.2.1 Isopropanol. The volatile diluent shall be isopropyl alcohol in conformance with the

requirements of grades A or B of TT-I-735.

3.2.2 Binder and dispersant. The binder and the dispersant shall be nonionic organic materials

which are not corrosive to metals. The binder and dispersant shall form a dry film which holds the

graphite to the surface to which the lubricant is applied. The lubricant shall not form a hard unstirrable

cake on settling in storage.

3.2.3 Graphite. Electric furnace graphite, 99 percent purity or higher, shall be used in the

preparation of the lubricant.

3.2.4 Dried solids composition (washed solids). Dried solids from the lubricant shall contain 75

percent 5 percent graphite (see 4.4.3).

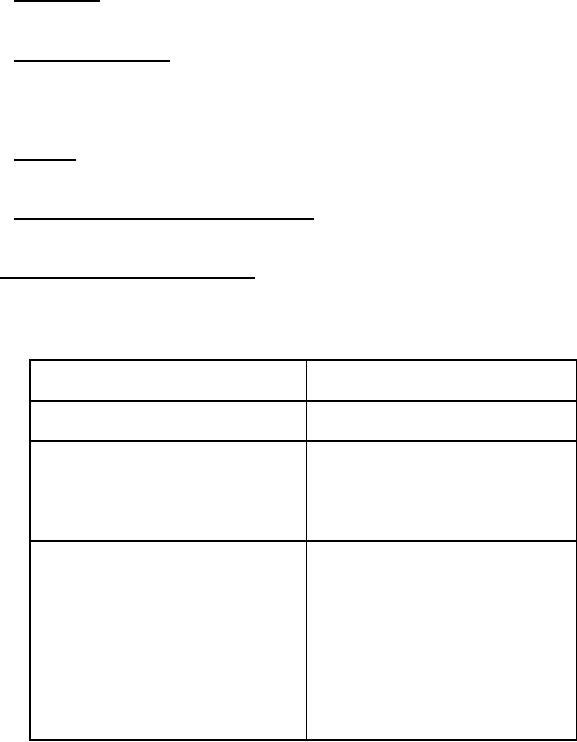

3.3 Physical and chemical requirements. Each batch of lubricant shall conform to the requirements

specified in table I.

Table I - Physical and chemical requirements.

Total solids content;

weight percent

3.3 0.5

Graphite content (percent of total

75 5

solids)

Particle size, microns

Maximum dimensions of 90

4

percent of the particles

10

Maximum dimension of any

particle

Ash; weight percent,

0.75

Maximum on total solids

Fluorine, parts per million, (ppm)

Maximum on total solids

20

Chlorine, parts per million,

200

Maximum on total solids

Sulfur, parts per million

Maximum on total solids

200

Lead, parts per million

Maximum on total solids

150

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |