|

|||

|

Page Title:

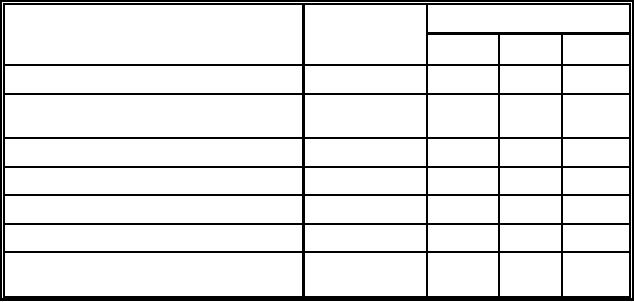

Modification of Type I liner formulation |

|

||

| ||||||||||

|

|  MIL-L-82653A(OS)

Weight Percent

Type I

Type II

Type III

Material

Specification

Liquid Polymer, CTPB

MIL-P-82658

83.312

--

86.814

Linear CTPB

MIL-P-23942

--

87.84

--

Type II

Carbon Black

DOD-C-82665

--

8.86

6.2325

Carbon Black, Thermal

DOD-C-82656

10.00

Chromium 2-Ethyl Hexoate

DOD-C-82660

0.124

--

0.0205

Epoxy Resin, Trifunctional

MIL-R-82657

6.564

--

6.933

Tris-1-(2-Methyl Aziridinyl) Phosphine Oxide

DOD-T-82666

--

3.30

--

Grade B

3.3 Modification of liner formulation.

3.3.1 Modification of Type I liner formulation. The properties of the Type I liner may be varied by

changing the ratio of epoxy resin to polybutadiene. The total weight percent of epoxy resin, catalyst, and

polybutadiene must remain constant at 90.0 percent.

3.3.2 Modification of Type II liner formulation. The properties of the Type II liner may be varied by

changing the ratio of Tris-1-(2-Methyl Aziridinyl) Phosphine Oxide to polybutadiene. The total weight

percent of Tris-1-(2-Methyl Aziridinyl) Phosphine Oxide and polybutadiene must remain constant at 91.14

percent.

3.3.3 Modification of Type III liner formulation. The properties of the Type III liner may be varied by

changing the ratio of epoxy resin to polybutadiene. The total weight percent of epoxy resin, catalyst, and

polybutadiene must remain constant at 93.7675 percent.

3.4 Propellant-to-liner bond strength. Propellant-to-liner bond strength testing shall be required before

a new liner ingredient lot set or liner formulation modification (see 4.3.1) is used. the propellant-to-liner bond

shall exhibit cohesive failure in the propellant web when tested at 77 5F.

3.5 Workmanship. The material shall be uniform and free from contamination and foreign material that

would prevent its use for the purpose intended.

4. QUALITY ASSURANCE PROVISIONS

4.1 Responsibility for inspection. Unless otherwise specified in the contract or purchase order, the

contractor is responsible for the performance of all inspection requirements (examinations and tests) as

specified herein. Except as otherwise specified in the contract or purchase order, the contractor may use his

own or any other facilities suitable for the performance of the inspection requirements specified herein, unless

disapproved by the Government. The Government reserves the right to perform any of the inspections set

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |