|

|||

|

Page Title:

Table VI - Dielectric test voltages. |

|

||

| ||||||||||

|

|  MIL-M-17059A(SHIPS)

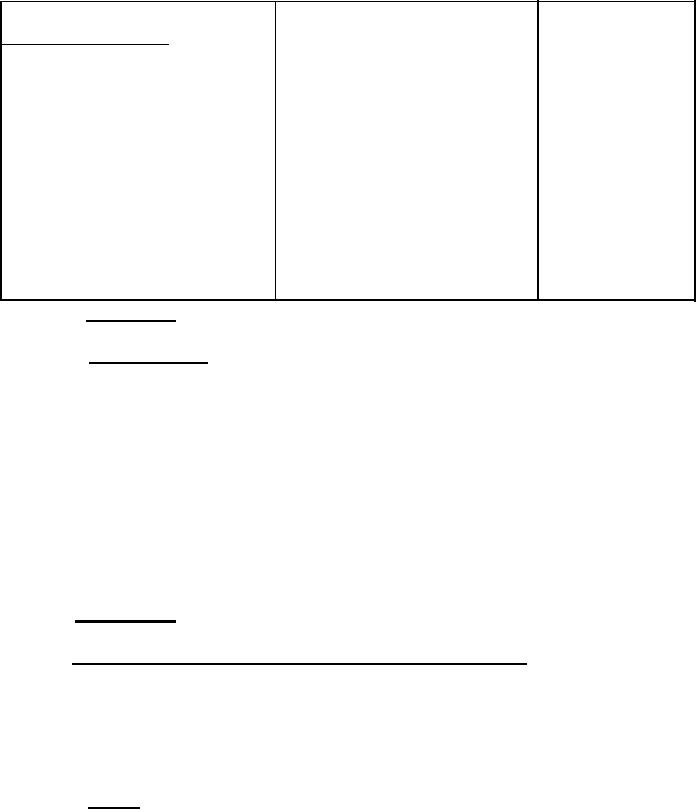

Table VI - Dielectric test voltages.

Minimum

Test voltage

Part

duration

Secondary windings of wound

rotors:

1,000 plus twice normal induced

1 minute

Nonreversing

voltage on open circuit.

1,000 plus four times normal

1 minute

Reversing, while running at

approximately normal speed

induced voltage on open circuit.

by reversing the primary con-

nections

Motors rated 1/2 H. p. and

1,000 plus twice rated voltage

1 minute

larger

Motors rated less than 1/2 H. P.

900 volts

1 minute

(a) Motors rated 250

volts or less

1,000 plus twice normal induced

(b) Motors rated over

1 minute

250 volts

voltage on open circuit

3.1.14.1 Alternate test. - An alternating-current test voltage of 1.2 times the one-minute test voltage

specified above may be applied for 1 second as an alternative to the l-minute test.

3.1.15 Mechanical balance. - Motors shall be balanced at any load and speed in the operating range.

Windings not in mechanical symmetry shall have dummy coils. In general, the proper mechanical balance

shall be effected by the use of balance weights securely attached, (if bolts are used, corrosion-resistant

bolts and locknuts shall be used), removal of material, securely welded steel weights, or by metal carried

in a receiver in such a manner as to preclude its breaking loose. Balancing by the use of solder on the

banding wire is permissible subject to the following limitations:

(a)

Peripheral speed not to exceed 6,500 feet per minute at rated load.

(b)

All armatures to be balanced before the windings are inserted.

(c)

Only tinned banding wire is to be used.

(d)

The solder not to cover an arc of more than 25 percent of the circumference of the armature

measured on the banding wire unless satisfactory to the bureau or agency concerned. Where

the manufacturer prebalances the armature and takes care in placing the windings in the

slots to reduce unbalance due to axial misalignment of the coils, this value may be increased

to 33 percent if satisfactory to the bureau or agency concerned.

(See 3.5.1.5 for service A and 3.5.1.17.5 for submarine requirements.)

3.1.16 Frame and feet. - The frame shall be of rigid construction. The feet shall be machined and

the holes for holding-down bolts may be either drilled or slotted.

3.1.17 End shields (explosionproof and explosionproof, fan-cooled excluded). - An accurate shoulder

joint shall be provided between the frame and end shields. When so specified (see 6. 1), the design of the

end shields shall provide for the rotation of the shields through 90 degrees or 180 degrees in either direction

to allow for bulkhead or underside suspension of the motor. Resilient-gaskets shall not be placed between

any bearing support member and the frame in such a manner as to affect the alignment of the bearing. In

the case of spraytight, watertight and submersible motors, the contact surfaces between the enclosing covers

and the motor frame or end shields shall be free from fins, burrs, or other imperfections detrimental to

watertightness, and shall be provided with "O" rings or gaskets suitably secured and treated with graphite

on the contact surface to prevent sticking. All sheet packing shall be securely attached to the covers.

3.1.17.1 General. - The end shields shall be secured by not less than two machine screws or through

bolts of suitable size and strength. These machine screws or through bolts may be furnished with either

screw-driver slots or hexagon-head screws.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |