|

|||

|

Page Title:

Bearing pre-load washers or springs |

|

||

| ||||||||||

|

|  MIL-M-17059A(SHIPS)

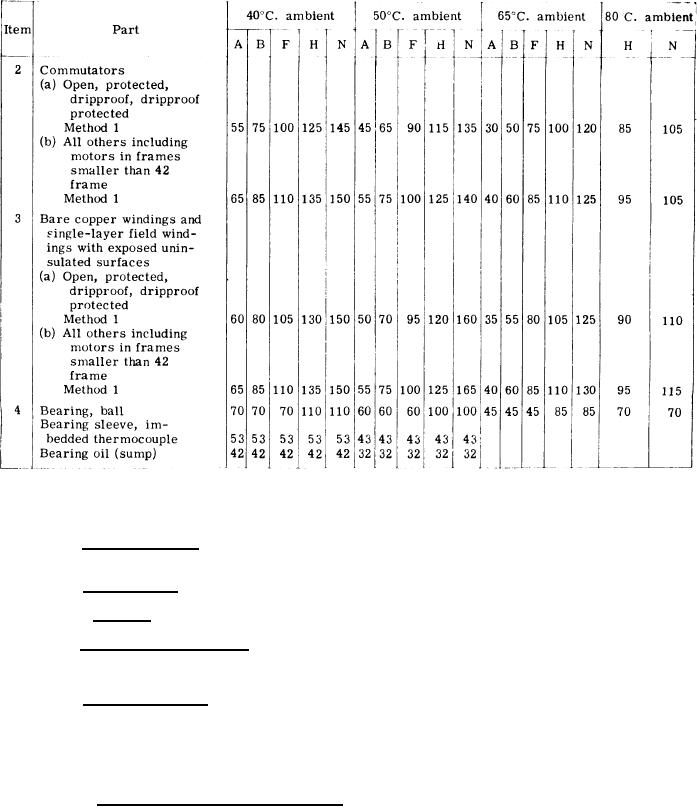

Table IX - Maximum permissible temperature rises (cont'd.).

NOTE: Squirrel-cage and mechanical parts (such as brush holders, brushes, pole tips), may attain such

temperatures as will not injure the motor in any respect.

3.5.1.3 Shock

resistance. - The motors shall be capable of withstanding the high-impact shock test

specified in MIL-S-901 and 4.3.4.16.

3.5.1.4

Ball

bearings. -

3.5.1.4.1

Mounting.

- The bearings shall be mounted as follows:

(a) Opposed shoulder method. - Where this method is employed, the end play of the shaft. shall be

adjusted to compensate for any relative movement that may occur between the shaft and the

housing due to temperature differential between these parts. In no case shall this end play

exceed .045 inches.

(b) Fixed-free method. - When this method is employed, the bearing shall be secured on the shaft

by means of locknuts and lockwashers or by a locknut utilizing a nylon insert to effect locking.

The pulley end or back end bearing shall be clamped axially in the housing by suitable housing

and end cap shoulders. End caps shall be secured by screws or bolts in such a manner that

the screws or bolts shall be capable of being removed without dismantling the motor. For

gear motors the front end bearing shall be clamped in the housing.

3.5.1.4.2 Bearing pre-load washers or springs. - Bearing pre-load washers or springs or both may

be used to attain required end-play.

16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |