|

|||

|

|

|||

| ||||||||||

|

|  MIL-M-17059A(SHIPS)

replaced in the event of minor deformation. Minor deformations affecting align-

ments, including alignments with the auxiliary, shall be corrected. Minor de-

formations shall be defined as those which do not cause unqualified rejection of

the design under the high-impact shock test but which are in excess of the dimen-

sional tolerances specified on the applicable motor drawing. Prior to acceptance

of the motor, all ball bearings shall be replaced.

(i) Shock extension. -

Motor shock test approval may be extended from the longest core length (same outside

diameter and similar construction) to a motor of a shorter core length. The manu-

facturer shall submit a letter of request together with the drawings of each motor.

Upon receipt of bureau or agency approval, the manufacturer shall note on the master

plan the test number and date or original shock test, the inspector's approval letter,

serial number and date and a statement of shock extension including bureau or agency

approval letter.

(j) Where the motor will be shock tested as part of an overall package, shock test of the motor

alone is not required.

4.3.4.17 Encapsulation. - The encapsulated stator shall be submerged in tap water for a period of 8 hours

with full load current applied. The insulation resistance (see 40.4.1 of appendix II) shall be measured before

and after the submergence period. The tested motor shall be hosed off with tap water and dried. The insula-

tion resistance shall again be measured. Insulation resistance value lower than that specified in 3.1.28.l(d)

shall be cause for rejection of the stator.

4.4 Service C. -

4.4.1 Inspection of repair parts for service C motors shall be as specified in 4.3.2. Inspection of service

C motors shall consist of the tests specified in table XV.

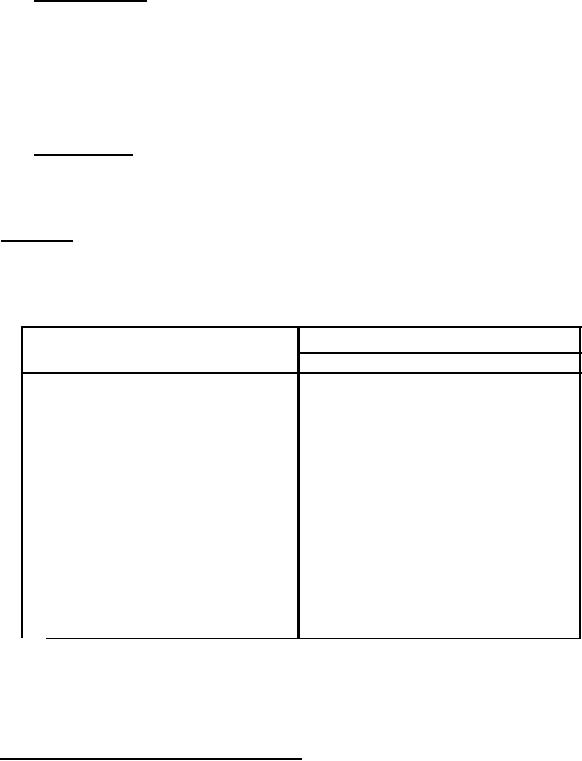

Table XV - Service C tests.

Applicable test paragraph

Description of test

Periodic tests

Routine tests

4.3.4.1

4.3.4.1

Material

Resistance (cold only)

4.3.4.2

4.3.4.2

4.3.4.5.2

4.3.4.5.2

Dynamic balance (by hand)

End play:

Sleeve bearing motors

4.3.4.6.1

4.3.4.6.1

Ball bearing motor

4.3.4.6.2

4.3.4.6.2

----

No-load input (induction motors)

4.3.4.7

----

Load test

4.3.4.14

Pull-up, breakdown and locked

----

rotor torque

4.3.4.8

Dielectric strength

4.3.4.9

4.3.4.9

----

----

Effectiveness of enclosure

Submersible

4.3.4.10

4.3.4.10

Explosionproof - subsequent test

----

waived

4.3.4.10

----

All others

4.3.4.10

----

Weight

4.3.4.13

Encapsulation

4.3.4.17

4.3.4.17

4.4.1.1 Each motor shall be subjected to a thorough examination to ascertain that the material, work-

manship, and design are in conformance with this specification. The fit of parts shall be observed with

particular reference to the interchangeability of such parts as are likely to require replacement during the

normal service life of the motor.

5. PREPARATION FOR DELIVERY

5.1 Preservation, packaging, packing and marking. - Motors together with their repair parts shall be

preserved, packaged, packed, and marked in accordance with the applicable levels of MIL-E-16298 (see 6.1).

29

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |