|

|||

|

Page Title:

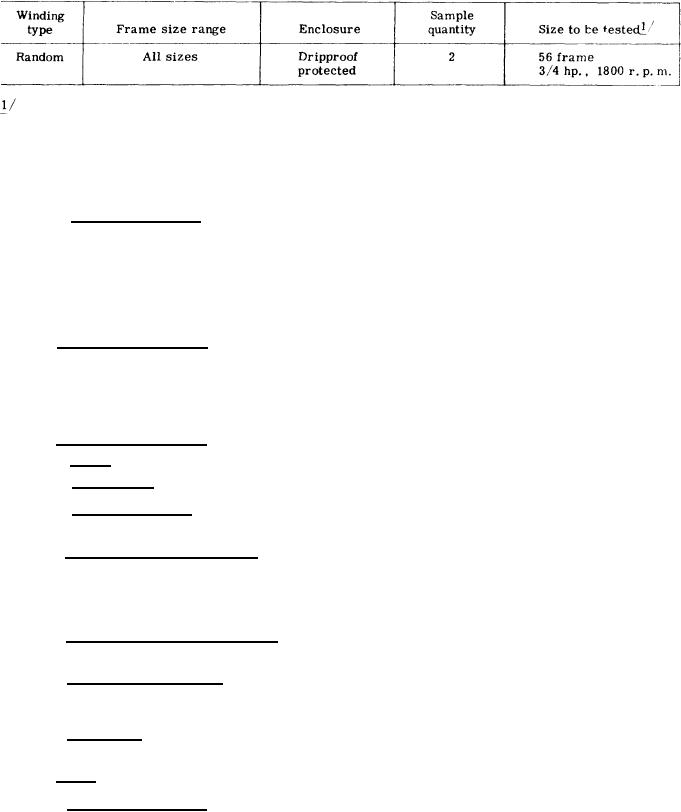

Table XVI - Specimens for encapsulated motor suitability test. |

|

||

| ||||||||||

|

|  MIL-M-17059A(SHIPS)

Table XVI - Specimens for encapsulated motor suitability test.

Motors presented for test shall preferably be production motors rather than laboratory prototypes. A

minimum of one complete motor and one stator will be required for the test. If laboratory prototypes

are furnished the encapsulation system used shall be a system suitable for production use. The prototype

may use corrosion protection methods that need only be sufficient for the 500 hour submergence test.

Motors shall be designed to give full load, rated output horsepower when operated in air. The motors

shall be tested at no load when submerged in water. Fans may be removed for this test. The motors

shall not stall when tested under these conditions.

40.1.3 Application for test. - Application for test shall be submitted to the Bureau of Ships, Code 660,

and shall include the following:

(a) Manufacturer's name and address.

(b) Test specimen rating and type of encapsulated motor winding.

(c) Availability of test facilities including manufacturer's name and designation or style number for

each equipment or instrument.

(d) Master drawing including complete details of proposed encapsulating procedures and materials

to be used.

40.2 Test equipment needed. - The following test equipment shall be provided:

(a) Chiller and submergence test tanks.

(b) Potential test equipment.

(c) Insulation resistance test bridge.

(d) Capacitance test bridge.

(e) Ohmmeter.

40.3 Type of test equipment. -

40.3.1 Tanks. -

(a) Chiller tank. - A tank shall be provided with an open top design. Water used shall be 4 percent

salt water and the water temperature shall be maintained between 0 - 3C.

(b) Submergence tank. - A suitable size tank shall be provided. Water used shall be 4 percent salt

water and the water temperature shall be adjusted so that it does not exceed 40 2C.

40.3.2 High potential test equipment. - Any standard high potential test equipment of suitable capacity

may be used provided the frequency of the test voltage is not less than 60 nor more than 100 cycles per

second (c. p.s. ) and provided the wave shape approximates a true sine wave. The test voltage shall be

measured with a voltmeter deriving its voltage from the high-voltage circuit either directly or through an

auxiliary ratio transformer or by means of a voltmeter coil placed in the testing transformer.

40.3.3 Insulation resistance test bridge. - A megohm bridge shall be used having a direct current test

voltage of 500 volts and with a range of 0.1 to 1,000,000 meghoms.

40.3.4 Capacitance test bridge. - A capacitance test bridge shall be used having a 60 c.p.s. input with

a range of 5 micromicrofarads to 1100 microfarads and with a range of dissipation factor of zero to 50 per-

cent. It shall be suitable for measuring circuits to ground.

40.3.5 Ohmmeter. - Any standard laboratory instrument may be used provided the smallest center

scale reading is not over 15 ohms.

40.4 Tests. - In addition to the tests required in 4.3.3 the following apply:

40.4.1 Insulation resistance. - This test shall be made before the dielectric tests. Prior to the ap-

plication of the test voltage, the windings of the motor shall be thoroughly discharged by connecting the wind-

ings to the frame. The time of test voltage application shall be not less than 60 seconds. The temperature

of the motor windings at the time of the test shall be measured and recorded. Insulation resistance

42

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |