|

|||

|

Page Title:

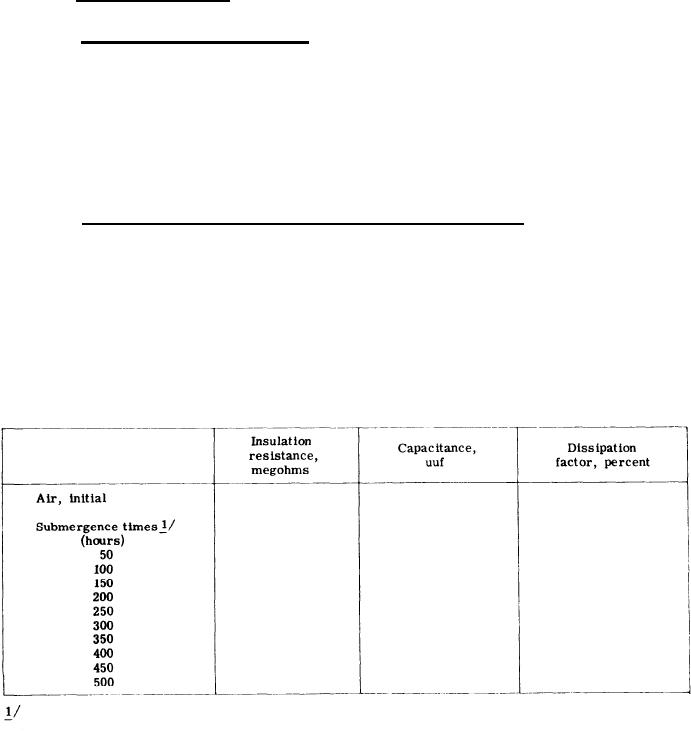

Table XVII - Submergence test data. Sample #1 Ser. No. |

|

||

| ||||||||||

|

|  MIL-M-17059A(SHIPS)

40.5.2 One motor of each type. - Sample motors of the type specified in table XVI shall be subjected to

the following tests:

(a) Submergence test for the 1st motor. -

(1) Photographs of encapsulated stator winding shall be taken and condition of all parts noted

and recorded.

(2) Measure and record insulation resistance, capacitance, and dissipation factor in air.

(3) Submerge motor in salt water and run 500 hour test. Record and measure insulation re-

sistance, capacitance, and dissipation factor after each 50 hour period. This time may be

adjusted to suit the work day. Bearings should be replaced after each 100 hours or sooner

if inspection reveals bearing failure is imminent.

(4) Upon completion of submergence test a normal potential test shall be applied and motor

shall be inspected and condition of all parts noted and recorded. Photographs of en-

capsulated stator winding shall be taken.

(b) Temperature cycling test for the 2nd motor (stator only need be used). -

(1) Photographs of encapsulated stator winding shall be taken.

(2) Measure and record insulation resistance, capacitance, and dissipation factor in air (cold

stator).

(3) Heat sttor in an oven at 130C 3C. for a 22 hour period and measure hot insulation re-

sistance, capacitance, and dissipation factor.

(4) Remove from oven and immediately (within 5 minutes) submerge stator in chilled water

tank until winding temperature (by the resistance method) reaches 10C. (within one-half

hour). Measure insulation resistance, capacitance, and dissipation factor.

(5) Repeat 3 and 4 nineteen times.

(6) After completion of test a normal potential test shall be applied and the stator shall be in-

spected and the condition noted. A photograph of the stator shall be taken.

Table XVII - Submergence test data. Sample #1 Ser. No.

This time may be adjusted to suit the work day.

Normal potential test.

Inspection report.

Photographs.

44

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |