|

|||

|

Page Title:

Test limit compensation examples. |

|

||

| ||||||||||

|

|  MIL-M-38510/61C

6.5 Abbreviations, symbols, and definitions. The abbreviations, symbols, and definitions used herein are defined

in MIL-PRF-38535, MIL-HDBK-1331, and as follows:

GND ............................................

Ground zero voltage potential

VOTH .............................................

High-level threshold output voltage

VOTL .............................................

Low-level threshold output voltage

VITH ..............................................

High-level threshold input voltage

VITL ..............................................

Low-level threshold input voltage

VEEL .............................................

Shifted power supply voltage for the purpose of ac testing

TJ ................................................

Circuit junction temperature

TC ................................................

Case operating temperature

PD ................................................

Circuit power dissipation

θJC ................................................

Junction to case thermal resistance

6.6 Logistic support. Lead materials and finishes (see 3.3) are interchangeable. Unless otherwise specified,

microcircuits acquired for Government logistic support will be acquired to device class B (see 1.2.2), lead material

and finish A (see 3.3). Longer length leads and lead forming should not affect the part number.

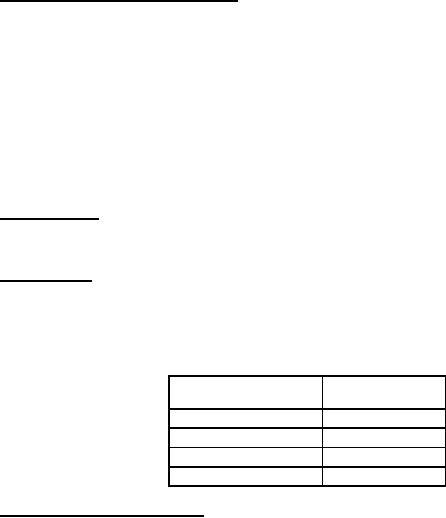

6.7 Substitutability. The cross-reference information below is presented for the convenience of users.

Microcircuits covered by this specification will functionally replace the listed generic-industry type. Generic-industry

microcircuit types may not have equivalent operational performance characteristics across military temperature

ranges or reliability factors equivalent to MIL-M-35810 device types and may have slight physical variations in relation

to case size. The presence of this information should not be deemed as permitting substitution of generic-industry

types for MIL-M-38510 types or as a waiver of any of the provisions of MIL-PRF-38535.

Military device

Generic-industry

type

type

01

10531

02

10631

03

10576

04

10535

6.8 Test limit compensation examples.

a. A device which has a power dissipation of 100 mW in case F is to be tested under a zero airflow condition.

on figure 15, ĆTJ between 500 linear ft/min and zero airflow is +4C. In order to adjust the various parameter

limits, use figure 16 which defines the limit adjustment coefficients for ĆTJ. To adjust VOH(max) at -55C, use

the +ĆTJ column of the -55C portion of figure 16 and locate the coefficient corresponding to VOH(max). This

value is 1.25 mV/C. Multiply the ĆTJ by the coefficient and algebraically add it to the -55C VOH(max) limit

from table III.

VOH(max) (adjusted limit) = (+4C) x (1.25 mV/C) + (-880 mV)

= 5 mV -880mV = -875 mV

Use 875 mV

Follow the same procedure to adjust the remaining parameters at -55C as well as all parameters at 25C and 125C.

b. A device with a power dissipation of 150 mW in case E is to be tested at an airflow of 200 linear ft/min and

the 25C testing is to be accomplished at an ambient temperature of +20C. On figure 14 ĆTJ due to airflow is

+3C. The ĆTJ due to ambient temperature change is -5C (25-20). Therefore the total ĆTJ = -5 +3 = -2C.

Using figure 16 find the 25C, -ĆTJ column. To adjust the VOL (max) for a negative ĆTJ, this value is 0.44

mV/C. Multiply the ĆTJ by the coefficient and algebraically add it to the +25C VOL (max) limit from table III.

VOL (max) (adjusted limit) = (-2C) x (0.44 mV/C) + (-1620 mV)

= -.88 mV 1620 mV = -1620.88 mV

Use 1621 mV

Follow the same procedure to adjust the remaining parameters at +25C.

47

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |