|

|||

|

Page Title:

Table 1. Reinforcement construction. |

|

||

| ||||||||||

|

|  MIL-M-46861B (MI)

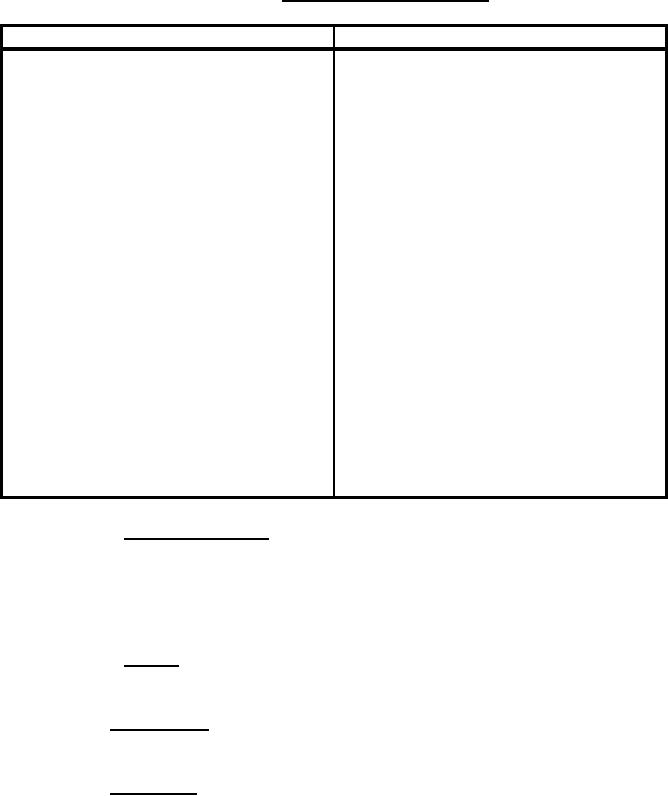

TABLE I.

Reinforcement construction.

Component

Definition

Unidirectional roving - continuous

8-end, K-37 fiber, per MIL-R-60346,

type I,class 1

Chopped strand

G-(135-140) fiber, per MIL-R-60346, type

I, class 1 - 1 to 4 inches, random length

Surfacing mat

0.010 with compatible finish

Glass sizing - all reinforcement

Chrome silane or silane finish, 3% by

weight maximum

Mechanical needling, approximately

Mechanical binding

180/square inch, over entire surface area

through all reinforcing components

Width

As specified 0.25 inches (see 6.2)

Selvage

None - clean cut with no loose roving

Length

50 10 linear yards. One splice per roll

allowed. Flag each splice at roll end.

3.2.3.3 Roving distribution. The material shall be such that 80 percent of the

construction is free of roving crossover. The gap between roving shall be not greater

than 0.150 inch. A fine thread of single glass fiber, K-37 , may be interlaced at 90 to

the unidirectional roving at intervals of approximately 0.5 inch to control roving

spacing (see 4.8.13).

3.2.3.4 Weight. The weight of the bare material shall be 2.50 0.25 ounces

per square foot (see 4.8.14).

3.2.4 Resin system. The resin system shall consist of epoxy resin conforming

to MIL-R-9300, type I, grade 0, form A, modified with a suitable elastomer (see 4.8.2).

3.2.5 Storage life. The materials as furnished by the manufacturer shall be

capable of meeting the requirements specified herein after storage in the original

unopened containers at a temperature not greater than 4 Celsius (C) for not less than

90 days (see 4.8.4).

4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |