|

|||

|

|

|||

| ||||||||||

|

|  MIL-M-48245B (AR)

4.5.5

Silica properties.

4.5.5.1 Particle size distribution. The silica particle size

distribution shall be determined in accordance with ASTM-B-214 using

the required sieves.

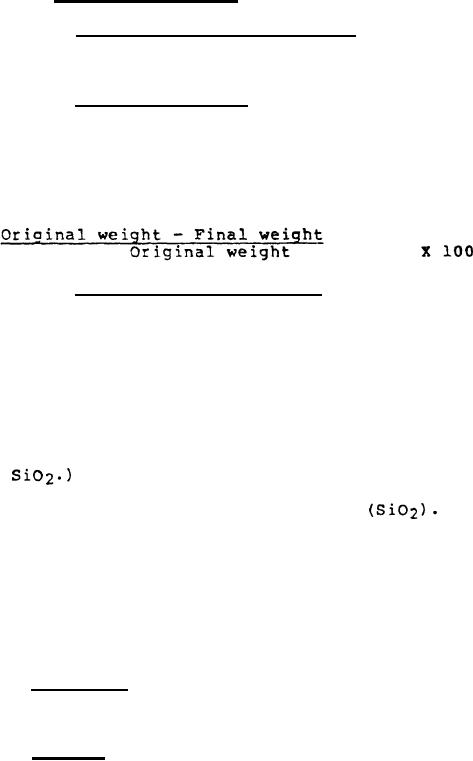

4.5.5.2 Loss on ignition. The loss on ignition shall be

determined by drying a sample of the lot of silica at 200

10F for 24 hours minumum. A 5 gm sample shall then be accurately

weighed placed in a muffle furnace and ignited at 950 15C

for a minimum of two (2) hours. The sample shall be cooled in a

desiccator and reweighed. The percent of loss on ignition shall be

calculated as follows:

4.5.5.3 Silicon dioxide content. The silicon dioxide content

may be determined by the wet analysis method as follows:

Weigh accurately about 0.5 gram of the material. Transfer to a

250 ml beaker and boil for 30 minutes with 50 ml of hydrochloric

Filter on a double ashless filter

acid (1:1). Add 50 ml water.

Transfer filter and residue to a tared platinum

paper . Wash.

dish.

Ignite.

Weigh the insoluble residue. The insoluble residue

shall then be volatilized with 0.5 ml of sulfuric acid and 10 ml

(1:1) hydrofluoric acid.

(Add the hydrofluoric acid very cautiously

to avoid mechanical loss from the vigorous reaction set up between

Ignite to drive off white

Evaporate under a hood.

HF and

fumes, then weigh. The loss in weight in the insoluble residue from

Repeat acid

volatilization will be the total silica

digestion until weight loss on repetitive trials is less than 2%

difference.

The contractor may use x-ray analysis or other suitable test

method if approved by the Contracting Officer and submitted as

specified in 4.4.4.

PACKAGING

5.

5.1 Packaging. The base resin and hardener shall each be

packaged in widemouthed containers as specified by the procuring

agency.

5.2 Marking. All marking shall be clear and legible and shall

include as a minimum:

Manufacturer's name

Item identification and lot number

Date of manufacture

Title and date of revision of this Military Specification

Safety precaution warnings

19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |