|

|||

|

Page Title:

Table II - Onboard repair parts. |

|

||

| ||||||||||

|

|  MiL-P-17881D(SHIPS)

3.6.2 For pumps operating at a temperature over 300F., whether to be insulated or

not, all external unmachined surfaces of ungalvanized ferrous metal parts shall be thor-

oughly cleaned and coated with two coats of heat-resisting paint in accordance with TT-P-28.

.

3.7 Pump drivers and accessories.

3.7.1 Turbines. All turbines for driving boiler feed pumps shall be in accordance "

with the requirements of MIL-T-17523 and as specified (see 6.1). Turbines shall be

l quipped with a low feed pump suction pressure trip to protect the feed pump in the event

of loss of suction, unless such a device is incorporated in the pressure governor. The

trip shall be designed to cause loss of turbine governor oil pressure whenever the feed

Pump suction pressure drops to trip set-point. The low suction pressure trip shall be

equipped with a manual reset. The trip shall be designed to have an adjustable set-point

over the pressure range specified (see 6.1).

3.7.2 Pressure regulating governors. Pressure regulating governors for turbine

driven boiler feed pumps shall be in accordance with MIL-G-18916 and of the type and

characteristics as specified (see 6.1).

3.7.3 Recirculation. The pump will be installed with a recirculation line leading

from the pump discharge back to the system deaerator, whereby a minimum through-flow is

assured to prevent pump damage. The recirculation line including the flow limiting pres- "

sure breakdown device will be furnished by the installer. However, the pump supplier shall

determine and indicate on appropriate installation drawings the amount of through-flow

necessary to prevent pump damage when the pump is operating continuously at shut-off at

rated design speed.

3.7.4 Motors. All motors for driving boiler feed pumps shall be in accordance with

MIL-H-17060 for alternating current (a.c.), or MIL-H-17413 for direct current (d.c.) motors

as specified (see 6.1). The horsepower rating of each motor shall be not less than the

maximum brake-horsepower of the driven pump under any condition from shut-off to free

delivery.

3.7.5 Controllers. All controllers furnished shall be in accordance with MIL-C-2212

#

for a.c. or d.c. controllers as specified (see 6.1). When specified, motor driven pumps

shall have a low suction pressure trip designed to de-energize the motor at the pressure

set-point specified (see 6.1).

.

3.8 Repair parts and tools.

.

--

3.8.1 Onboard. Repair parts shall be furnished and processed in accordance with

#

MIL-P-15137 (see 6.2) and as specified hereinafter.

3.8.2 A set of repair parts (onboard) shall be furnished in accordance with method B

#

(paragraph 3.3.2) of MIL-P-15137 (see 6.2) and for guidance in preparing provisional technical

documentation shall consist of the parts specified in table II, and special tools and wrenches

required for servicing of the pump.

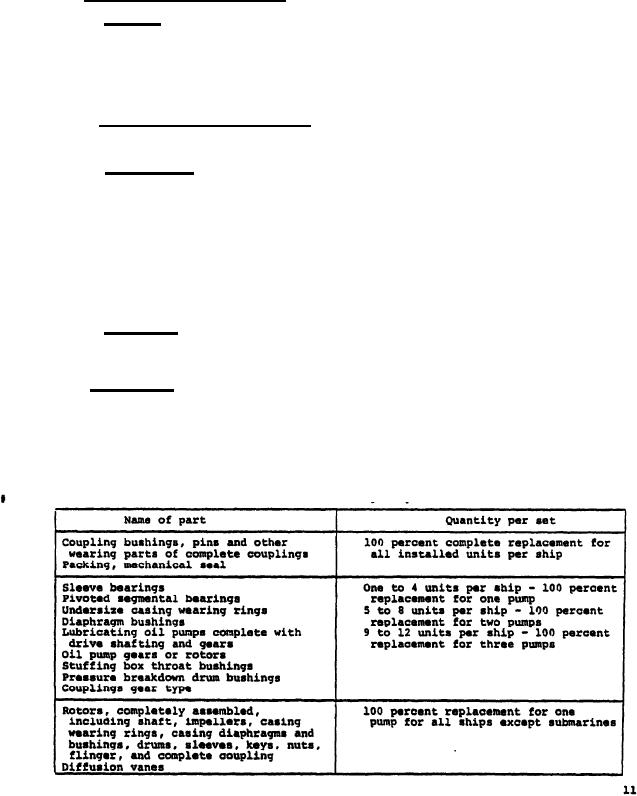

Table II - Onboard repair parts.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |