|

|||

|

Page Title:

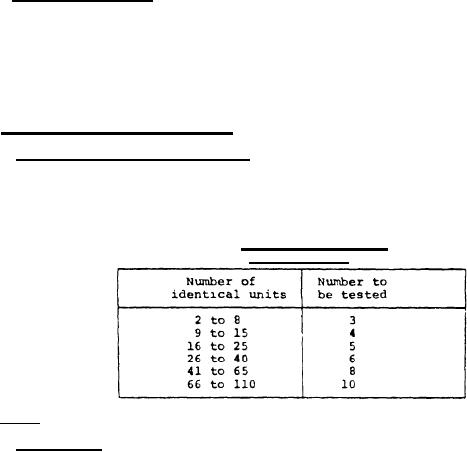

Table III. Sampling for design Proving Tests |

|

||

| ||||||||||

|

|  MIL-P-17945A(SH)

contractor iS responsible for the performance of all inspection requirements as specified

herein. Except as otherwise specified in the contract, the contractor may use his own or any

other facilities suitable for the performance of the inspection requirements specified here-

in, unless disapproved by the Government. The Government reserves the right to perform any

of the inspections set forth in the specification where such inspections are deemed necessary

to assure contractors and services conform to prescribed requirements.

4.1.1 Inspection system. The contractor shall provide and maintain an inspection

system in accordance with the data and ordering documents included in the contract or order

(see 6.2.2).

4.1.2 When specified (see 6.2.1) , the pump shall be free of all mercury contamination,

During the manufacturing process, tests, and examination, the product to be offered for

acceptance shall not come in direct contact with mercury or any of its components nor with

any mercury containing device employing a single boundary of containment. The manufacturer

shall certify that the product, when shipped, is free from mercury contamination.

4.2 Quality conformance

inspection.

4.2.1 Samp ling for performance tests.

4,2.1.1 For a packaged tank and pump unit, a representative number of sets in accord-

ance with table III shall be tested to demonstrate the ability of the unit to function

properly insofar as the start-stop of the pump, pressure switch, and air volume control are

concerned.

Sampling for design-

TABLE III.

proving tests.

4.3 Tests.

4.3.1 Performance.

4.3.1.1 Driving units shall be tested as required by the applicable equipment specifi-

cations.

4.3.1.2 One complete pump of each size on order, including the motor and controller,

shall be given a test to determine the overall power consumption of the unit under the

specified conditions. The Naval Ship Engineering Center (NAVSEC) may consider waiver of

overall power consumption tests on pumps if identical units have been previously tested

satisfactorily.

4.3.1.2.1 Performance tests shall ordinarily be conducted at the same time as, and

shall include the inclined operation tests as specified for the driving unit. For inclined

operation tests the unit shall be run at maximum operating speed, but need not be fully

loaded.

4.3.1.3 Performance tests shall demonstrate the ability of the pump to handle its rated

capacity of specified liquid at the maximum temperature and minimum suction head or maximum

suction-lift or vacuum as applicable.

.

4.3.1.4 The following test curves shall be submitted:

Capacity

versus

total head.

(a)

pump efficiency.

(b)

Capacity

versus

bhp .

(c)

Capacity

versus

electrical horsepower input.

(d)

Capacity

versus

10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |