|

|||

|

|

|||

| ||||||||||

|

|  MIL-P-18472G(SH)

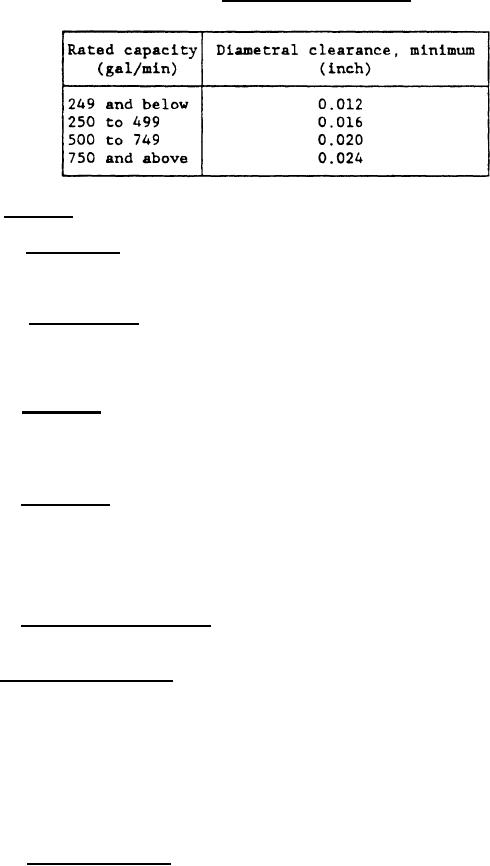

TABLE I. Diametral clearance.

3.3.6 Shafts.

3.3.6.1 Threading. Shaft threading, except threading for rolling contact

bearing locknuts, shall be counter to the direction of rotation. Shaft threading

for rolling contact bearing locknuts may be clockwise or counterclockwise.

3.3.6.2 Tachometers. The shaft (pump or driver), except those driven by ac

motors, shall be provided with means to permit the ready and direct use of

portable tachometers. When this is impracticable, provision shall be made for

the use of a portable tachometer on the shaft of the driver.

3.3.6.3 Sleeves. Shafts shall be fitted with shaft sleeves in way of all

wearing surfaces, such as stuffing boxes, bushings, and water lubricated

bearings. An O-ring seal shall be installed between the shaft and stuffing box

(including mechanical seal) shaft sleeve.

3.3.6.4 Flingers. Shaft flingers shall be provided adjacent to the gland

for all pumps. The flinger shall be so located that leakage which might occur

between the gland shaft sleeve and the shaft, as well as from the gland, is not

allowed to reach pump or motor ball bearings. For rigid coupled units, the

coupling may serve as the pump flinger provided the coupling is constructed of

corrosion-resistant material.

3.3.6.5 Close-coupled pumps.

Shafts of close-coupled pumps shall be of

one-piece construction.

3.3.7 Rotating assembly. Rotors shall be dynamically balanced with all

rotating parts connected thereto; for common shaft assemblies, or those using

rigid coupling, this requires dynamic balance with the rotating element of the

driving unit in place. However, rotating parts may be balanced individually

provided that, when assembled, the imbalance shall not exceed the limits

specified in MIL-STD-167-1. Where balancing is required as a maintenance

procedure to maintain proper vibration or noise performance of the pump and

driver unit in service, the pump shall be configured so that balancing may

readily be performed by overhaul activity personnel.

3.3.7.1 Operating speed. The pump construction shall be such and calcu-

lations shall be made to demonstrate that the maximum operating speed of the

pump is not greater than 70 percent of the first critical speed.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |