|

|||

|

Page Title:

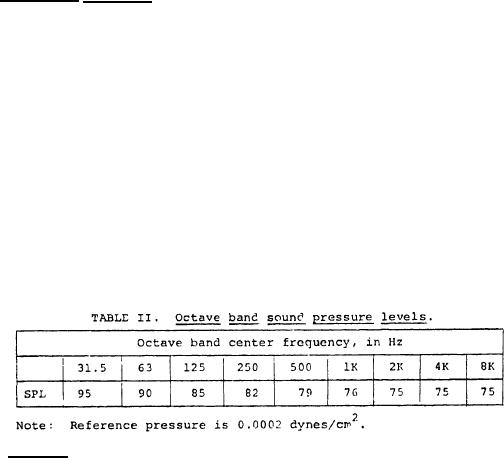

Table II. Octave Band Sound Pressure Levels |

|

||

| ||||||||||

|

|  MIL-P-18526A(SH)

3.3.3 Shock and vibration.

3.3.3.1 Pumps with drivers, appurtenances, and controls, shall be capable of passing

a shock test in accordance with MIL-S-901, as specified in 4.4.3.8.

3.3.3.2 Shock mounts (resilient mounts for shock attenuation) shall not be used.

When noise attenuation mounts are specified, pumps shall be designed to pass the shock test

on standard Navy noise attenuation mounts in accordance with MTL-M-17508,

3.3.3.3 Bolts stressed in shear shall be installed in holes with a minimum of clearance.

Hole diameters shall be no more than 1/32 inch larger than the bolts for sizes up to and

including 3/4 inch, and no more than 1/16 inch larger than bolts of greater than 3/4 inch

size. Mounting bolts for fastening the equipment shall conform to grade 2 or better of MIL-

S-1222.

3.3.3,4 Pump units shall not be damaged or caused to malfunction either by internally

excited vibrations, or by the environmental vibrations specified in MIL-STD-167-1. Frequen-

cies shall be tested up to and including 33 hertz (Hz) .

3.3.3.5 When required (see 6.2.1), pumps shall be designed and tested to meet the

airborne noise requirements of MIL-STD-740 and as specified herein. The contractor shall

obtain noise measurements in accordance with the requirements, measurements, and data report-

ing procedures as contained in MIL-STD-740. Equipment shall not exceed the airborne noise

criteria identified in table II.

3.3.4 Mounting.

3.3.4.1 Pump units shall be horizontally or vertically mounted, as specified (see 6.2.1).

Each horizontal pump and driving unit shall be mounted on a common bedplate.

3.3.4.2

3.3.4.3 Each vertical unit shall be base mounted or table mounted, as specified (see

6.2.1).

3.3.4.4 A bracket shall be provided between the pump and driver of vertical units.

3.3.4.5 Bedplates, bases, table mounts, and brackets shall be sufficiently rigid to

permit handling, shipment, and installation of the units onboard ship to minimize misaline-

ment of the assembled units and such that the normal distortion, weaving, or vibration of

the supporting structures onboard ship shall not cause misalinement betweeen the pumps and

driving units. The driver shall be capable of being doweled and the unit realined by the

installing activity after final installation. The contractor shall furnish a warning plate

advising of the above requirement.

3.3.4.6 Each component part of an assembled flexible coupled unit supported directly

by a bedplate shall be doweled thereto to facilitate reassembly and maintenance of alinement

except that final doweling of the driver shall be performed by the installing activity after

final installation.

3.3.4.7 Bearing and seating surfaces of bedplates, bases, table mounts, and brackets

shall be machine finished.

3.3.4.8 Equipment shall not be rigidly supported from more than one plane.

3.3.4.9 In the event special bulkhead mounting is required, sideplates shall be fur-

nished subject to the conditions specified for baseplates (see 3.3.4.1 through 3.3.4.8) .

3.3.4.10 Each vertical unit, in order to facilitate interchangeability, shall be con-

structed to permit rotation of the pump with respect to its driver. Eight or more positions

of pump flanges relative to the driver shall be available.

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |