|

|||

|

|

|||

| ||||||||||

|

|  MIL-P-19380/1

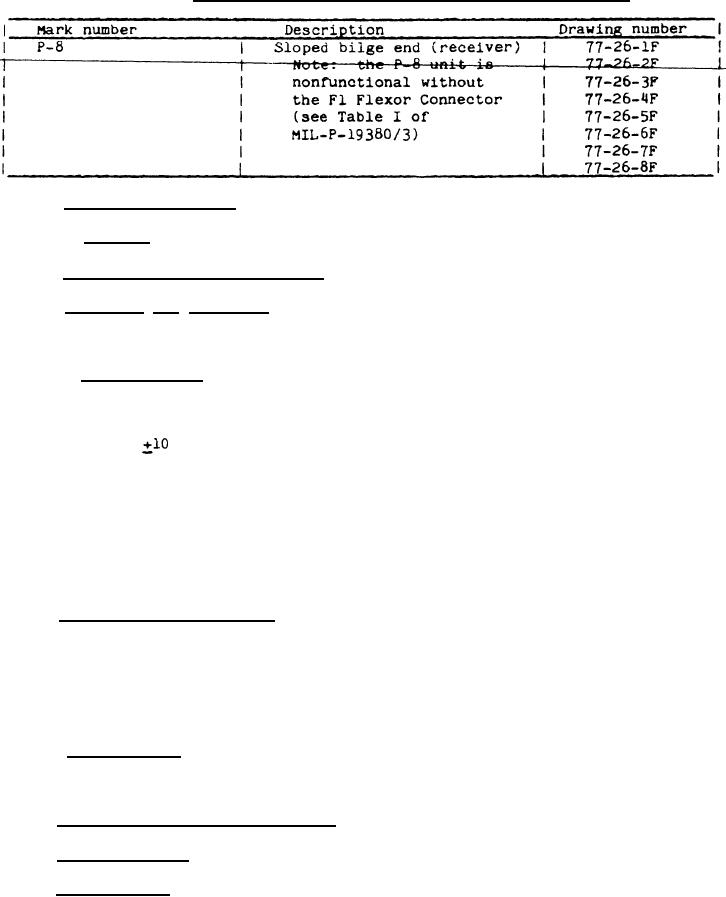

TABLE I.

Pontoons, steel sectional, P-series - contined.

3.6 Interchangeability.

(See 3.6 of MIL-P-19380J.)

3.6.1 Gaging.

(See 3.6.1 of MIL-P-19380J.)

3.? Performance

characteristics.

(See 3.7 of MIL-P-19380J.)

3.8 Cleaning and painting.

(See 3.8 through 3.8.2.2 of MIL-P-19380J.)

When knocked-down pontoons are called for (see 6.2), omit finish coat

described in 3.8.2.2 of MIL-P-19380J.

3.8.1 Deck coating. In addition to the three coat epoxy-polyamide paint

system applied to all exterior surfaces, the pontoon deck surface shall be

coated with No, 36076, dark gray, nonskid finish coating conforming to

MIL-D-23003, type II. Coating shall be uniformly applied at the rate of

1 gallon per 60

square feet of surface, using airspray or a smooth, hard

phenolic core roller. Finished deck coating shall have a profile where the

aggregate prominently protrudes above the binder surface. Threaded surfaces

and gages shall not be painted. All painted areas shall be touched up where

paint is removed as a result of handling or assembly at the manufacturing

plant. The pontoon deck surface requiring deck coating is defined as the top

of the pontoon as seen in NAVFAC Drawing No. 77-26-1F when viewing the pontoon

from the end having the manhole, the pipe plugs being to the left of the

manhole.

3.9 Identification marking. (See 3.9 of MIL-P-19380J.) In addition, all

pontoons shall be marked with a one-pass single weld bead, 3/16-inch wide

minimum, 1-inch high digit/letter identification consisting of two digits, a

dash, and one letter. The two digits shall denote the year, followed by a

letter assigned to identify the manufacturer, e.g., 80-A. This information is

to be applied to the 7-foot long side containing the manhole, with the top of

the numbers 3 inches from the top of the pontoon and centered.

3.10 Workmanship.

(See 3.10 through 3.10.5 of MIL-P-19380J.)

4.

QUALITY ASSURANCE PROVISIONS

4.1 Responsibility for inspection.

(See 4.1 of MIL-P-19380J.)

4.2 First article.

(See 4.2.1 of MIL-P-19380J.)

4.3 Examination. Examination shall be conducted as specified in Table I

of MIL-P-19380J.

Examination of components and welds inside the pontoon shall

be completed before the manhole is welded in place. (See 4.5 of MIL-P-19380J.)

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |