|

|||

|

|

|||

| ||||||||||

|

|  MIL-P-26366A

checked through 5 pitch change cycle-s for

minutes. The rotational speed shall be reduced

proper operation. Upon completion of the 15-

to zero, during which time the propeller shall be

day test, the propeller shall be dried without

placed in the air start position by the time the

forced convection for 12 hours in air at less than

rotation reaches zero. The ambient tempera-

70 F with not less than 15 percent relative

ture shall be reduced to 65F at the specified

humidity. At the conclusion of this period,

altitude as rapidly as practicable. As soon as

four over-voltage power supply transients in ac-

this temperature and altitude condition has been

cordance with Standard MIL-STD-704 shall be

reached, rotation of the propeller shaft shall be

applied. Operation of the propeller shall be

started and increased to takeoff rpm. The pitch

checked at normal input voltages, for normal

change sequence noted above shall be followed

operation. The propeller shall be disassembled

once every 80 minutes during an 8-hour con-

and inspected. No corrosion or other defects

tinuous run at the specified altitude and am-

shall be present that affect the function or struc-

bient temperature. After each sequence of

tural strength of the propeller.

pitch change, the rate of pitch change at 25

propeller rpm overspeed and underspend at the

high and low beta angle limits shall be deter-

mined. The ice control system shall be subjected

to operation at the specified altitude without

current flow. A determination of the effect of

current flow shall also be performed, The wear

rate of the brushes and rings shall be such as

to indicate a total wear life compatible with the

desired propeller overhaul period of 1,500

hours. The following data shall be recorded at

sea level and altitude conditions, as applicable:

Altitude

Ambient temperature

Rotational speed of propeller

4.6.2.7 Sand and dust. The propeller shall

Feather motor temperature

be installed in a test chamber so that the air

Reference motor temperature

stream will strike the forward face of the as-

Governor temperature

semlly at a velocity of 100 feet per minute. The

Sump oil temperature

air shall carry sand and dust at a concentration

Power unit temperature

of l.50.4 grams per cubic foot. The sand and

Feather motor current. and voltage

dust used shall consist of more than 90 percent

Blade angle movement during pitch change

S i o2, shall be angular in structure, and shall

Sump pressure

screen as follows:

Degree of oil aeration

100-mesh screen US Standard Sieve Series

Beta high and low angle

passes 100 percent.

Mechanical reference on-speed

140-mesh screen US Standard Sieve Series

Electrical reference on-speed

passes 982 percent.

Rate of pitch change at 25 rpm underspeed

200-mesh screen US Standard Sieve Series

Rate of pitch change at 25 rpm overspeed

passes 902 percent.

Centrifugal switch operating rpm

325-mesh screen US Standard Sieve Series

This test shall be accomplished five separate

passes 752 percent.

times.

The temperature of the circulating air shall be

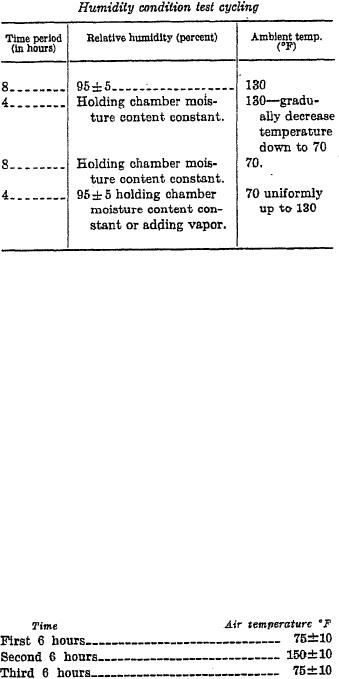

4.6.2.6 Humidity. The propeller, including

controlled as follows:

the ice control system, shall be subjected to an

atmosphere of clear water vapor under cycle

conditions specified as follows for a period of

15 days. After 12 hours, the propeller shall be

41

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |