|

|||

|

Page Title:

Table II. Properties of glass fiber reinforced PEEK (type II) |

|

||

| ||||||||||

|

|  MIL-P-46183

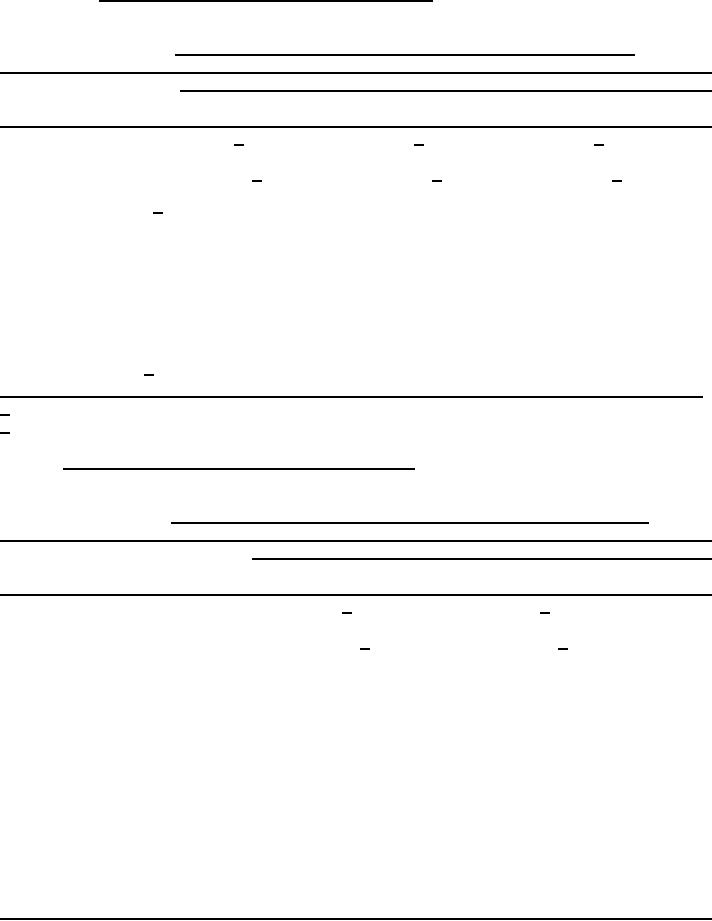

3.2.2 Glass fiber reinforced PEEK (type II). The properties of glass fiber

reinforced PEEK thermoplastic shall be as specified in table II.

TABLE II.

Properties of glass fiber reinforced PEEK (type II).

Property Values

Property

Class 1

Class 2

Class 3

(l0% glass fiber)

(20% glass fiber)

(30% glass fiber)

Glass fiber content

l0 + 2% (by wt)

20 + 2% (by wt)

30 + 2% (by wt)

Specific gravity

1.37 + 0.04

1.44 + 0.04

1.49 + 0.04

Tensile strength 1/

110 MPa

120 MPa

152 MPa

(minimum)

(16,000 psi)

(17,400 psi)

(22,000 psi)

Elongation at break

5%

4%

3%

(minimum)

Flexural modulus

5000 MPa

6200 MPa

6900 MPa

(minimum)

(730,000 psi)

(900,000 psi)

(1,000,000 psi)

Impact strength 2/

50 J/m

60 J/m

80 J/m

(minimum)

(0.9 ft-lbf/in)

(1.1 ft-lbf/in)

(1.5 ft-lbf/in)

1/ MPa x 145 = psi

2/ Notched, 0.25 in; J/m x l8.73 x l0-3 = ft-lbf/in

3.2.3 Carbon fiber reinforced PEEK (type III). The properties of carbon

fiber reinforced PEEK thermoplastic shall be as specified in table III.

TABLE III.

Properties of carbon fiber reinforced PEEK (type III).

Property Values

Property

Class 1

Class 2

(20% carbon fiber)

(30% carbon fiber)

Carbon fiber content

20 + 2% (by wt)

30 + 2% (by wt)

Specific gravity

1.38 + 0.04

1.42 + 0.04

Tensile strength

159 MPa

185 MPa

(minimum)

(23,000 psi)

(27,000 psi)

Elongation at break

5%

2%

(minimum)

Flexural modulus

10,300 MPa

12,800 MPa

(minimum)

(l,500,000 psi)

(1,850,000 psi)

Impact strength (minimum)

(notched, 0.25 in)

45 J/m

50 J/m

(0.8 ft-lbf/in)

(0.9 ft-lbf/in)

(unnotched, 0.25 in)

400 J/m

530 J/m

(8.0 ft-lbf/in)

(l0.0 ft-lbf/in)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |