|

|||

|

Page Title:

Table II. Quality conformance inspection |

|

||

| ||||||||||

|

|  MIL-P-47099A

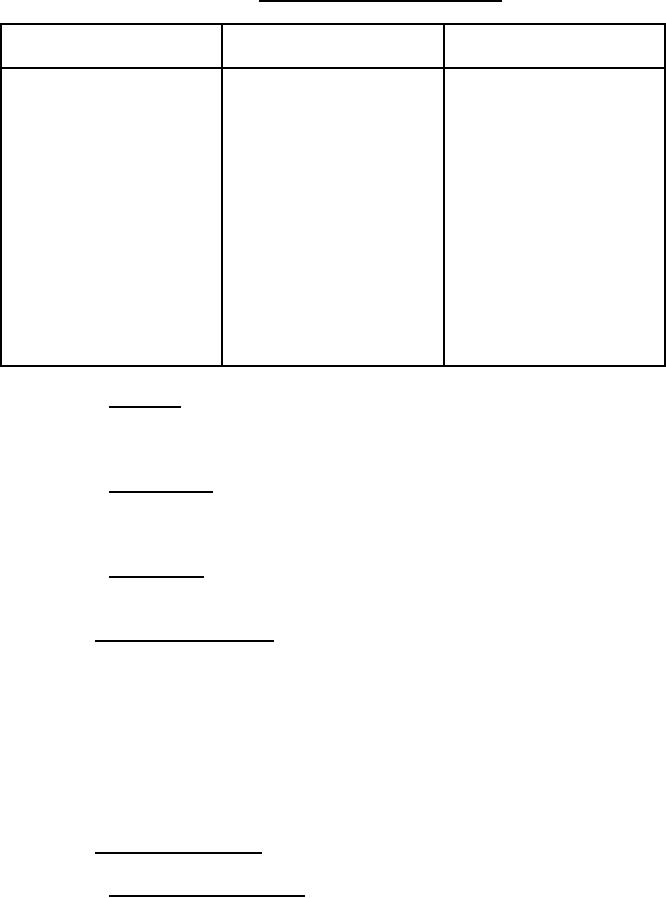

TABLE II. Quality conformance inspection.

Requirement

Test

Inspection

paragraph

paragraph

4.7.2

3.4, table I

Density

4.7.3

3.4, table I

Tensile strength

4.7.4

3.4, table I

Compression strength

4.7.5

3.4, table I

Shear strength

4.7.6

3.4, table I

Dielectric constant

4.7.7

3.4, table I

Dielectric strength

4.7.8

3.4, table I

Dimensional stability

4.7.9

3.4, table I

Flammability

4.7.10

3.4, table I

Temperature resistance

4.7.11

3.4, table I

Humidity growth

4.7.12

3.4, table I

Fungus resistance

4.5.3

3.5

Workmanship

4.5.1 Sampling. For sampling purposes, a one pint kit containing all required

ingredients shall be considered as a sampling unit. The number of sampling units shall

be as specified by the procuring activity (see 6.2).

4.5.2 Lot formation. A lot shall consist of a batch of material manufactured in

one continuous operation by the same process, by the same manufacturer, using the

same batches of raw materials and submitted for 100 percent inspection at one time.

4.5.3 Examination. The polyether type polyurethane foam shall be examined

for compliance with the requirements specified in 3.2 through 3.5.

4.6 Inspection of packaging. Except when commercial packaging is specified,

the sampling and inspection of the preservation and interior package marking shall be

in accordance with groups A and B quality conformance inspection requirements of

MIL-P-116. The sampling and inspection of the packing for shipment and storage

shall be in accordance with the quality assurance provisions of the applicable container

specification shown in section 5. The inspection of marking for shipment and storage

shall be in accordance with MIL-STD-129. The inspection of commercial packaging

shall be as specified in the contract (see 6.2).

4.7 Methods of inspection.

4.7.1 Test specimen preparation. Utilizing the samples selected as specified in

4.5.1, the test specimens shall be prepared as specified in the applicable test method.

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |