|

|||

|

|

|||

| ||||||||||

|

|  MIL-P-47215B (MI)

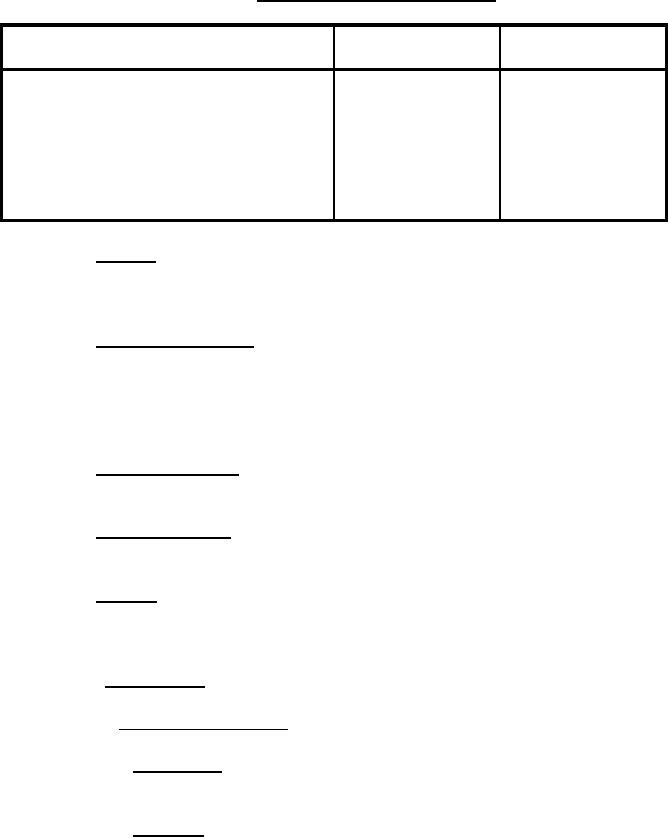

TABLE I. Quality conformance inspection.

Inspection

Requirement

Test paragraph

paragraph

4.3

3.1

First article

4.6

3.2

Material

4.10.1.1

3.3.1

Appearance

4.10.1.2

3.3.2

Viscosity

4.10.1.3

3.3.3

Alkalinity

4.10.1.4

3.3.4

Shelf life

4.12

3.4

Workmanship

4.5 Lot size. Lot size shall consist of all the primer submitted for acceptance

at the same time which has been prepared by the same company without a change in

materials or processes in one continuous period of operation.

4.6 Sampling of material. Unless otherwise specified (see 6.2), 0.5 pint of

primer from one unit representative of each lot shall be selected at random for quality

conformance inspection. Each packaged container shall be considered as a unit of

product. Failure of the sample to meet the quality conformance requirements shall be

cause for lot rejection.

4.7 First article sample. The first article sample shall be prepared using the

same methods proposed for the preparation of subsequent production lots of primer.

4.8 Inspection routine. Samples of the primer shall be subjected to all

examinations and tests specified herein.

4.9 Failures. First article samples which do not meet the requirements of this

specification shall be subjected to rejection. Subsequent quantities will not be

considered for acceptance until approval of the first article sample has been obtained.

4.10 Test methods.

4.10.1 Physical property tests.

4.10.1.1 Appearance. The appearance of the primer shall be checked visually.

Appearance shall be as specified in 3.3.1.

4.10.1.2 Viscosity. The viscosity shall be determined in accordance with FED-

STD-141, Method 4287, using a number 2 spindle at 2 revolutions per minute (rpm).

The viscosity shall be as specified in 3.3.2.

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |