|

|||

|

|

|||

| ||||||||||

|

|  4.4.3.5

Salt water supply. Salt water (6.3.5) shall be used as the

coolant . The salt water supply shall be capable of providing salt solu-

tion at a rate of 10 gpm at temperatures between +32' F and +98 F at a

pressure of 15 psig, measured at inlet test port.

4.4.3.6

Temperature indicator.

0 F to +140 F, accuracy to

Range:

= 2 F.

4.4.4

Test Procedures .

4.4.4.1

Operational test. Install the pump in the pump test stand and

connect to appropriate fittings in accordance with Figures 1 and 2. With

the drive unit operating the pump at 3880 10 rpm, the output pressure

shall be: 265: psig minimum. The pump shall operate for one complete

duty cycle of 7 minutes on salt water. Post-test servicing and mainten-

ance shall be performed in accordance with 4.5.7.

4.4.4.2

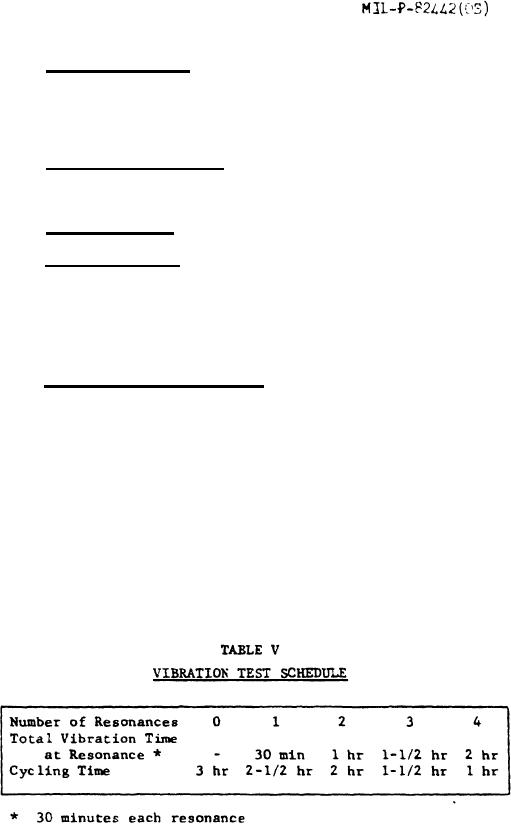

Vibration. ready condition.

The pump, in the ready condi-

tion, shall be mounted in a manner equivalent to that shown in Figure 1.

The resonant modes in each of the 3 axes shall be determined by varying

the frequency of applied vibration slowly from 5 cps to 500 cps. The

pump shall then be subjected to resonance and cycling vibration in each

axis , in conformance with the times shown in Table V. If more than 4

resonances are encountered on any axis, the 4 most severe resonances shall

be chosen for the test. The resonant and cycling period, for each axis,

shall be divided into 3 equal parts, which are conducted at -45 F 5 F,

room temperature and +140 F 5 F respectively, For cycling, a logarithmic

frequency sweep rate shall be used if available; othewise, other cycling

rates of frequency change may be used. The sweep-rate shall be such that

15 minutes actual vibration time is required to proceed from the lower

to higher and back to the lower extremity of frequency range in accordance

with the accelerations or double amplitudes defined in Table VI.

9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |