|

|||

|

Page Title:

Ultimate strain and yield stress tests |

|

||

| ||||||||||

|

|  MIL-P-82691A (OS)

Specific gravity test. The specific gravity of the

cured

4.7.1.1

be determined by the sink-float

propellant

shall

test

Zinc

solutions shall be used in this determination in

0. 002

chloride

increments. The value of the specific gravity of the cured

prope-

llant

shall be the specified gravity of the zinc chloride

sol u-

tion in which the sample of propellant just floats.

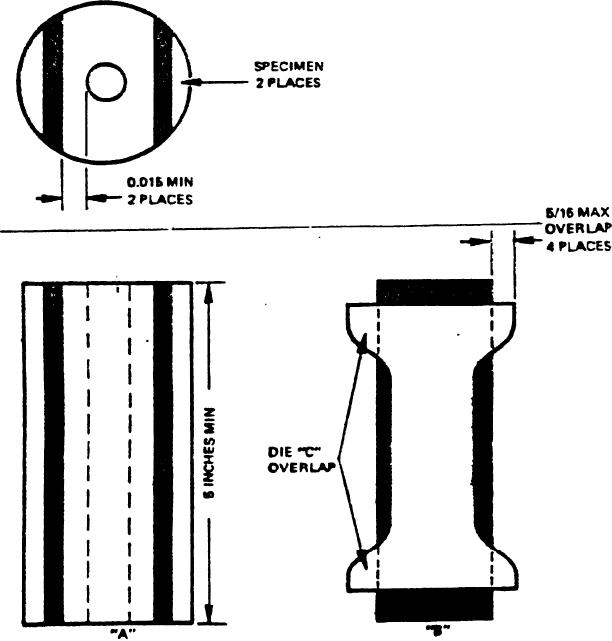

4.7.1.2 Ultimate strain and yield stress tests. A minimum of two

specimens

sample. 1 e.

test

shall be cut from each propellant

Each

shall be five inches minimum in length and

specimen

0.1000.050

inch in

Using Die C of

ASTM

thickness as shown in FIGURE IA.

D412, cut dumb-bells from the specimens as shown in FIGURE IB.

Three thickness measurements shall agree within 0.010 inch for

acceptable specimens. Reject any specimen that has surface imper-

fections

or

Replace unacceptable samples from the

15 damaged.

same propellant sample.

The testing machine shall have a recor-

der,

adjustable velocity and constant-rate-of-crosshead-movement

for

performing the ultimate strain and yield stress

tests.

The

rate shall be O. 10 inch per minute prior to yield

crosshead

and

The average

20 inches per minute from yield to the break point.

values shall be compared to Table I values for compliance.

FIGURE 1. Vibration set-up

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |