|

|||

|

Page Title:

Table III. Projectile body assembly |

|

||

| ||||||||||

|

|  MIL-P-85766(AS)

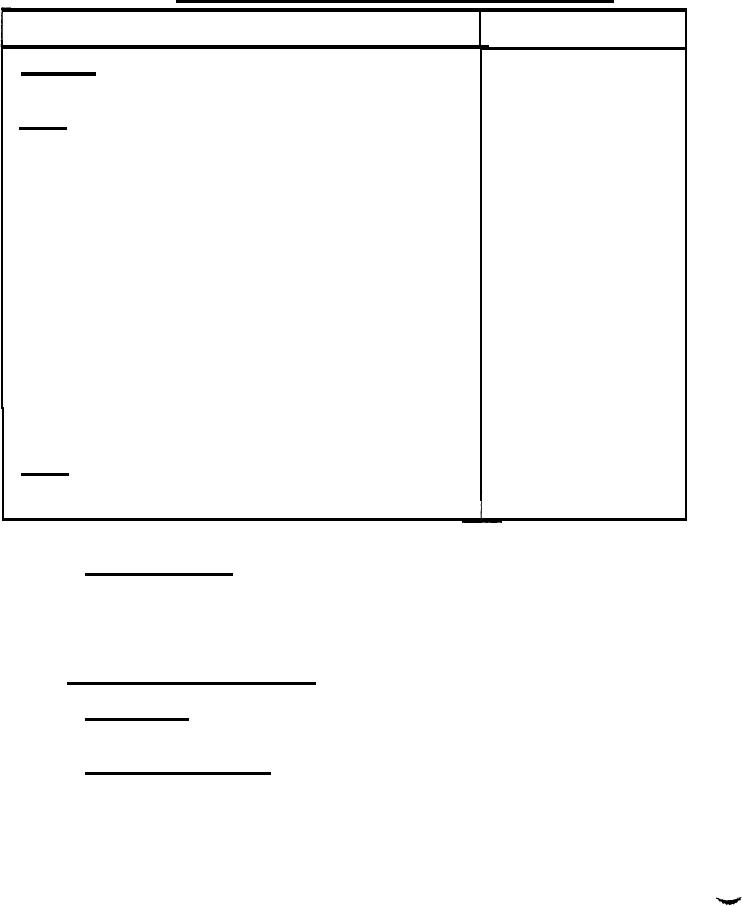

TABLE III.

Projectile body assembly (see Drawing 1575AS403).

Categories and defects

Method of inspection

---

CRITICAL:

None defined.

MAJOR:

1010

Length mouth to rear edge of rotating band

Gage

102.

Diameter bourrelet

Gage

Gage

103.

Diameter of rotating band

Position rotating band diameter

104.

Gage

Width rotating band

105.

Gage

106.

Location crimp groove

Gage

107.

Profile crimp groove

Gage

Radius, rear edge of crimp groove, maximum

108.

Gage

109.

Void at band/body interface

Visual

MINOR:

Finish

201.

Visual

4.4.4 Acceptance tests. The tests listed in Table XI shall be con-

ducted in compliance with the test methods and procedures described herein

(see 6.2.2). The samples shall be selected in such a manner as to be

representative of the entire lot. The sample size and acceptance criteria

for each test shall be as specified herein.

4.5 Test methods and procedures.

4.5.1 Performance. The projectile when assembled as part of a 20mm

cartridge, shall pass all the performance tests specified in MIL-C-85764.

4.5.2 Metal parts security. Metal parts security shall be in accordance

with AMCR 715-505, Volume 8. The test cartridges, at ambient temperature,

shall be fired in bursts of 50 shots in an M61 gun. The gun barrel shall be

at ambient temperature for the firing of each burst. The cyclic rate of

fire will be recorded for informational purposes. These tests shall be

carried out in accordance with the applicable tests of MIL-C-85764.

10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |