|

|||

|

Page Title:

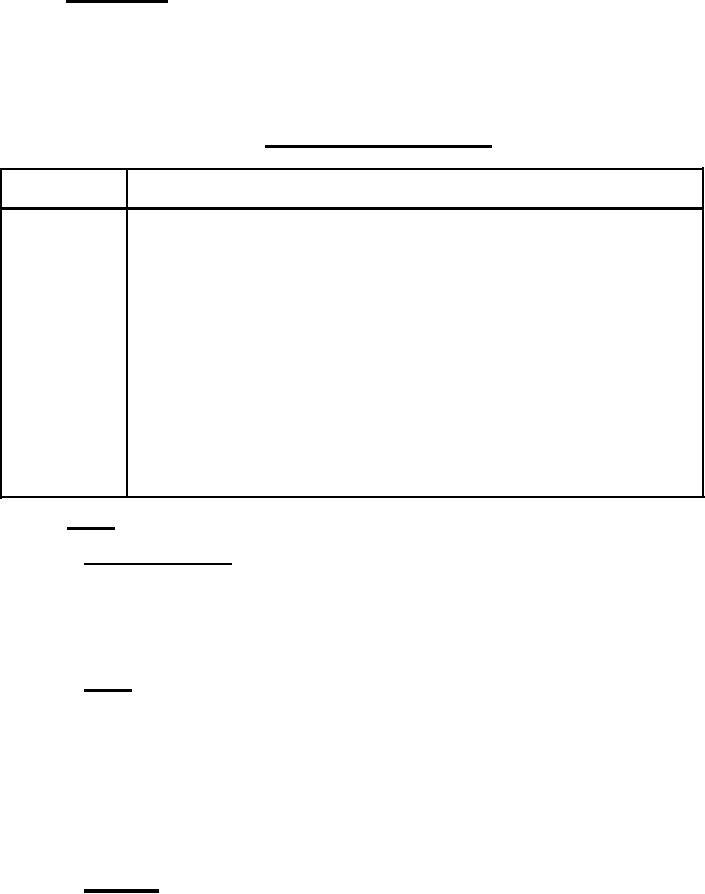

Table II. Classification of defects |

|

||

| ||||||||||

|

|  MIL-R-24159A(SH)

4.5 Examination. Each sample, selected in accordance with table I, shall

be visually examined to determine conformance with this specification. The

classification of possible defects in table II is the minimum that is to be

considered in the examination. Any receptacle in the sample containing one or

more defects shall not be offered for delivery and if the number of defective

units in any sample exceeds the acceptance number for the sample, this shall be

cause for rejection of the lot represented by the sample.

TABLE 11.

Classification of defects.

Defects

Categories

None defined.

Critical:

Major:

101

Incomplete, component parts missing or improperly assembled.

Materials defective or not as specified.

102

Limiting dimension exceeded.

103

Welding incomplete, not. free of cracks, nonfusion, heavy

104

porosity a Welding not in accordance with MIL-STD-278.

105

Drawing not followed.

Bolts, nuts and screws not tight, missing (parts shall be

106

properly fastened and secured).

107

Painting (as applicable) nonconforming.

108

Surfaces not smooth, evidence of sharp edges or burrs.

Marking, identification and information plate not complete,

109

missing, not permanent, illegible or not as specified

4.6 Tests.

4.6.1 Operational test. Each receptacle shall be energized to conform

to the requirements specified herein. Electrical metering equipment shall be

connected in the circuitry to demonstrate that current and voltage is within

rated values and that no shock hazard exists. Evidence of improper electrical

operation or personnel hazard and inability of the unit to deliver the proper

air quantity shall be cause for rejection.

4.6.2 Shock. The receptacle shall be subjected to the grade A, class 1,

type A, lightweight H.I. shock test in accordance with MIL-S-901 as specified in

3.4. For the purposes of the shock test, the three rubber bumpers on the bottom

of the casing shall be removed and replaced with l-inch diameter by 3/4-inch

thick steel stand-offs. The receptacle shall then be bolted solidly to the

mounting shelf of the lightweight high impact shock machine with three 1/4-20 NC

hex-socket-head cap screws. The test shall be conducted subsequent to tests

specified in 4.6.3. Evidence of fragmentation or missile effect of parts,

deformation that will cause active interference between parts, or leakage shall

.

be cause for rejection.

4.6.3 Air flow. An anemometer, pressure gage, or other measuring device

shall be used for the purpose of determining the air flows The measurements

shall be made with the canisters and filter in place.

7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |