|

|||

|

|

|||

| ||||||||||

|

|  MIL-R-24414D(SH)

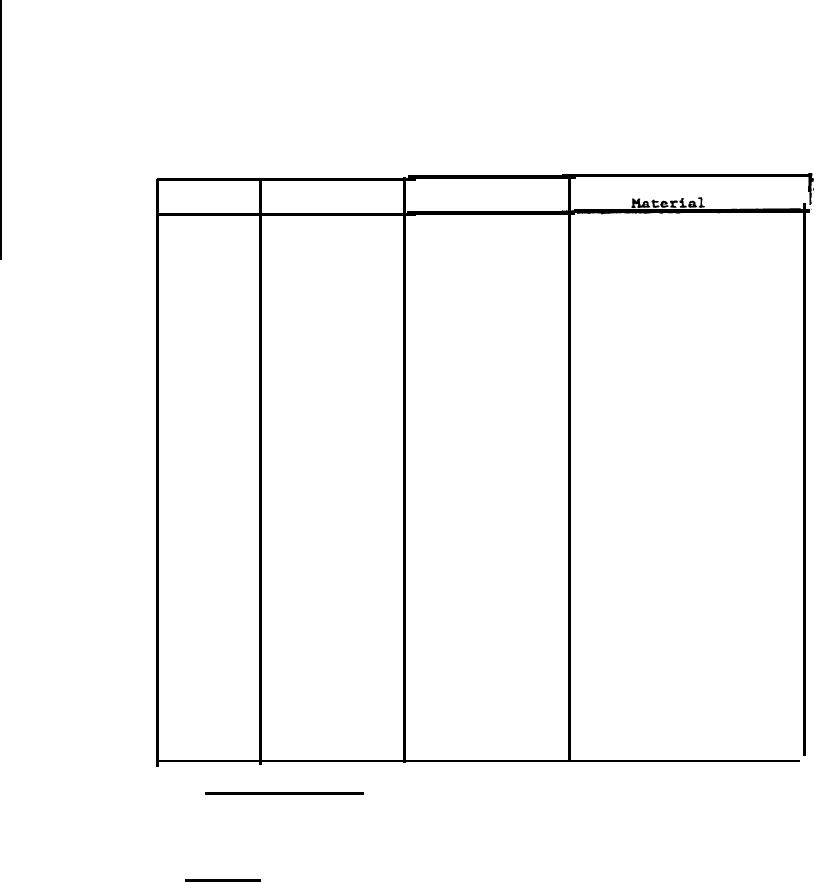

TABLE 111.

Material

Material

specification

Subassembly

GrouP

Aluminum bars

ASTM

A

366

Frame

A

Aluminum forgings

ASTM

B

211

Aluminum Sheet & plate

ASTM

B

209

Aluminum Extruded Bars

ASTM

B

221

Rods, Shapes

Bronze castings

ASTM B 62

Swing joint

Cres bars

ASTM A 276

and axle

Cres tubing

ASTM A 269

Aluminum bronze

MIL-B-24480

Fluid path

Cres tubing

ASTM A 269

Carbon steel bars

ASTM

A

336

Reel drum

Spring wire

ASTM

A

108

Brass rod, bar,

ASTM

A

229

and shapes

ASTM

B

16

Sand castings

ASTM

B

26

Aluminum Sheet & Plate

ASTM

B

209

Carbon steel,

Fasteners

FF-S-85

A and B

zinc plate

ASTM A 167

Chrome nickel

steel plate

Steel sheet

ASTM A 569

B

All

Cres

ASTM A 312

Carbon steel bars

ASTM A 108

In order to prevent galvanic corrosion, aluminum

3.2.1 D i ss i m l ar metals.

s

parts shall not be in direct contact with dissimilar metals such as copper alloys

or steel.

Where it is necessary that dissimilar metals are adjacent to one

another they shall be treated as follows for the protection of faying surfaces:

Alumi num Thoroughly cleaned with Oakite NC or equal, rinsed in dip tank

at 140 degrees Fahrenheit (*F) for 5 minutes and coated with

epoxy polyamide primer in accordance with MIL-P-24441 and

MIL-P-24441/1, or primer in accordance with class 1 of

MIL-P-23236.

Thoroughly cleaned, preferably by abrasive blasting and coated

Steel

with epoxy polyamide primer in accordance with MIL-P-24441/l

or primer in accordance with class 1 of MIL-P-23236.

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |