|

|||

|

Page Title:

Table IV. Quality conformance inspection. |

|

||

| ||||||||||

|

|  MIL-R-85363(AS)

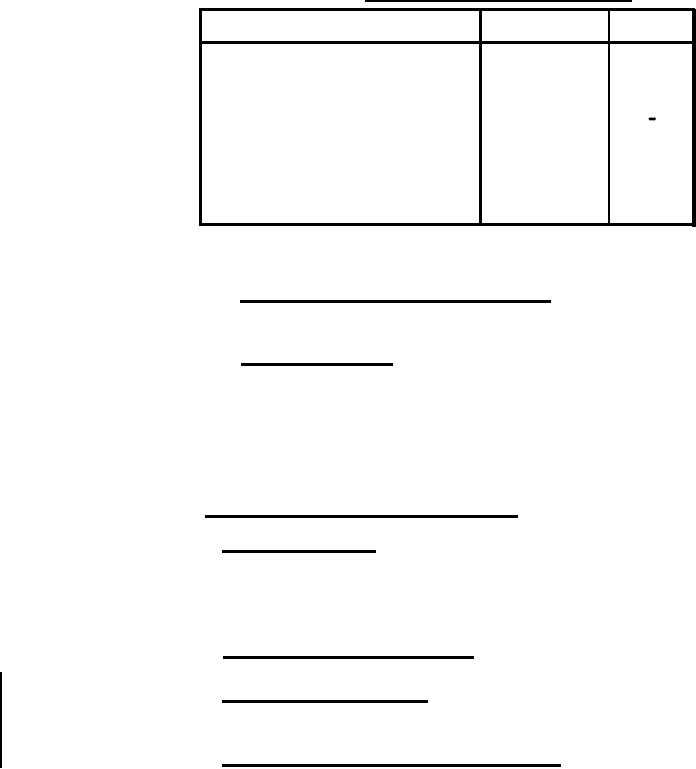

TABLE IV.

Quality conformance inspection.

Requirement

Inspection or test

Test

Visual inspection

3.4.1

4.6.1

-

Welding

3.4.2

-

Finish

3.4.3

Corrosion protection

3.4.4

Magnetic particle inspection

3.4.5

4.6.2

Radiographic inspection

4.6.3

3.4.6

Nozzle and body hydrostatic

proof test

3.4.7

4.6.4

Ballistics test

4.8

3.6

4,5.2 Sample size.

4.5.2.1 Nondestructive inspection and tests. Unless otherwise

specified in the contract, sampling for nondestructive inspections and

tests shall be in accordance with MIL-STD-105, level II, AQL 1.0.

4.5.2.2 Destructive tests. Two motors selected at random for

quality conformance test firings shall be selected from the same

motor lot. The motors shall be static fired after being temperature

conditioned at OF and 140F, respectively, for a minimum of 40 hours

in accordance with 4.7.1. If chamber pressure is to be obtained from

test firings, propellant grains may be randomly selected from the grain

lot and test fired in special test hardware provided such hardware

has been previously approved by the procuring activity.

4.6 Nondestructive inspection and tests.

4.6.1 Visual inspection. All rocket motors and components shall be

free from dents, scratches, split or cracked components, poor quality

welds, chipping or flaking of-plated or painted surfaces, sharp edges

or other defects or discontinuities as specified on the applicable

drawings.

4.6.2 Magnetic particle inspection. All ferromagnetic parts shall -

be inspected in accordance with MIL-I-6868 after hydrotest.

4.6.3 Radiographic inspection. Propellant grains and rocket motors

shall be subjected to a radiographic inspection in accordance with

MIL-STD-453.

4.6.4 Nozzle and body hydrostatic proof test. All rocket motor

nozzles and chambers shall be subjected to a hydrostatic proof test

in accordance with OD 14483 except that graphite nozzle inserts shall

be protected from contact with pressurizing liquid.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |