|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-13303G(AR)

4.5.2.3.2 Hand fired. The packed signals shall be conditioned

for a min. of 16 hours at a temperature -65 5F. The packed

signal shall be taken from the conditioning chamber, removed from

the metal container and fired vertically by hand (see 6.4) before

the temperature of the signal is allowed to change. The performance

of the signal shall be observed for compliance with the requirements.

4.5.2.4 Test validity. If for any reason the proving ground

considers that the test conditions have detrimentally affected the

test results, the test shall be declared invalid and a new test

shall be performed with additional samples.

4.5.3 Leakage. The packed sealed container shall be placed in

the test cylinder. Apply air in the cylinder to a pressure of 3 to

5 p.s.i. and hold for eight (8) seconds min. Observe pressure

indicator for a drop in pressure during the holding time.

(Non-Destructive Test)

4.5.4 Container tear strip test. The tear strip of the

container shall be tested in accordance with procedures specified in

MIL-C-10464 for compliance with the requirements specified.

(Destructive Test)

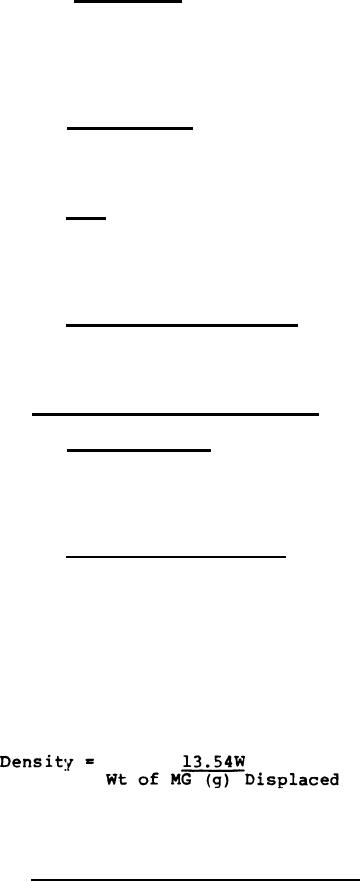

4.5.5 Density of propellant grain.

4.5.5.1 Overall density. The propellant grain shall be

accurately measured, the volume determined and converted to cubic

centimeters. The grain shall then be accurately weighed and the

density in grams per cubic centimeter calculated and compared with

the requirement.

4.5.5.2 Density of any section. Each of the grains shall be

cut into two (2) approximately equal size cylinders. Each cylinder

shall be accurately weighed. Fill the beaker with clean mercury,

(see figure 1) insert the immersing mixture and level off the

mercury by pressing down with the flat glass plate until it is even

with the top of the beaker. Then place the cylinder beneath the

prongs of the immersing fixture and level and mercury by pressing

down with the flat glass until it is even with the top of the

beaker. Catch the excess mercury in a clean evaporating dish.

Weigh the mercury displaced by the cylinder. Calculate the density

of the cylinder as follows:

where:

W = weight of the cylinder in grams

4.5.6 Hydrostatic test of casing tube. The casing tube shall

be tested in any hydrostatic test device capable of applying the

min. pressure for not less than 5 seconds. The tube shall be

observed for evidence of failure to comply with the requirements.

Any test sample which fails to comply with the applicable

requirement shall be classed defective and removed from the lot.

(Non-Destructive Test)

44

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |