|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-17000N(SH)

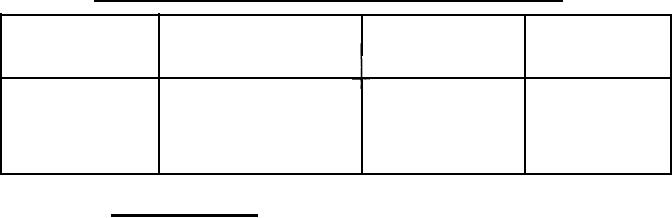

Ampere rating of rectangular bus bars placed on edge. - Continued

TABLE IV.

Size of bars

Cross sectional

A.c. ampere

D.c. ampere

(inches)

rating

rating

area

(inZ)

3

x

1/4

0.750

1,140

1,185

4

x

1/4

1,490

1 .000

1,425

5

x

1/4

1.250

1,760

1,850

2,190

6

X

1/4

1.500

2,100

3.6.23.8 Bus bar stresses. The bus work assembly shall withstand the

stresses resulting from the maximum available root mean square (rms) asym-

metrical short-circuit current (see 6.2.1). Conditions of H.I. shock which

may be encountered aboard the ship shall not mechanically damage the bus work

or reduce the bus clearances below minimum requirements. Where single conductor

cable is used for connection between bus bars and supply switches, the cable

shall be securely bound together with nonflammable cord and secured to the

supports as necessary to prevent distortion under short circuit conditions.

The binding shall be applied in such a manner that it will not cut into the

cable insulation due to the forces exerted under short circuit conditions.

The binding shall be especially heavy where cables turn out of the pack.

Terminal lugs shall be used for terminating cable at the switch terminals and

at the bus bars. Through-bolts shall be used for securing the cable terminal

to the bus bars. Not more than two cable terminals shall be clamped by one bolt,

and when two are used, they shall be placed on opposite sides of the bus. The

cables shall be neatly formed, and where their length exceeds approximately

12 inches, they shall be supported by the switchboard structure. For calcula-

tion of required spacing of bus supports to withstand the short circuit current,

the value of maximum stress in the outside fiber shall be based on the yield

strength of the copper and not upon the tensile strength.

3.6.23.9 Bus bars shall be accurately formed and holes shall be accurately

made so as to ensure that the bus bars can be fitted into place without being

forced. Flat bends shall have an inside radius of not less than the thickness

of bus bar, and the ends of the bus bars shall be neatly finished. Edgewise

bends of bars up to 2 inches in width may be made on an inside radius of 1 inch,

and those over 2 inches but not exceeding 4 inches in width may be made on an

inside radius of 2 inches. Bars of greater width cannot be bent edgewise, but

shall be bolted. Bars shall be free from cracks or flaws at bends.

3.6.23.10 Holes in bus bars for bolting may be

either punched or drilled,

but the contact areas shall be finished true, or an

equivalent method employed

to give adequate contact. Contact nuts and contact

spaced nuts for copper stud

contacts shall be of sufficient size to provide the

necessary contact surface

area.

in bus bar joints shall be of steel, coarse

3.6.23.11 Bolts and nuts, used

against corrosion. Flat washers of

thread series, and plated to protect

under all bolt heads and nuts adjacent to

similarly plated steel shall be used

be fitted with a securing nut and a lock

the conductor. Securing bolts shall

nut.

36

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |