|

|||

|

Page Title:

Sampling of links for proof test |

|

||

| ||||||||||

|

|  MIL-S-18313G

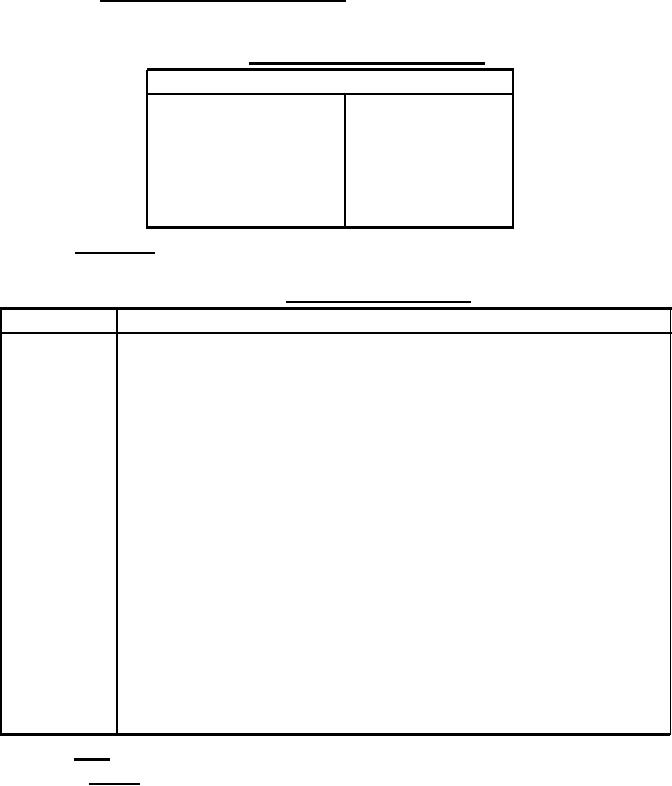

4.4.1.3 Sampling of links for proof test. Sample links shall be selected in accordance

with table II from the total quality of links required for the slings in each lot, prior to

galvanization and assembly with webbing for the test of 4.6.2. If any sample link fails in

this test, this shall be cause for rejection of all links.

TABLE II. sling of links for proof test.

Sample size

Number of links

2

4

to 16

3

20

to 40

5

44

to 68

7

112

to

72

10

300

to

116

500

to

15

304

504

800

25

to

804

to 1,300

35

1,304

to 3,200

50

3,204

75

to 8,000

4.5 Examination of slings. Each of the sample slings, selected in accordance with

defects classified as shown in table III to determine compli-

4.4.1.2, shall be examined

ance with the requirements of this specification which do not require tests.

TABLE III.

Classification of defects.

Defects

Categories

None defined.

Critical:

Major:

Slings not complete; parts missing.

101

Component parts not new; evidence of reclaimed, used, or salvaged

102

components.

Evidence of use of unauthorized materials or repairs.

103

Slings not size specified.

104

Hoist links not galvanized.

105

Link surface not smooth; not free of blisters, seams, laps, cracks,

106

or pit holes.

107

Link configuration and dimensions nonconforming to figure 2.

Webbing not of type specified, and are not free of splices.

108

Integral slots of webbing not woven with length and spacing as

109

specified.

Webbing not impregnated with type rubber latex compound required.

110

Flame-proof treatment of webbing nonconforming.

111

Evidence of use of dyes, detergents, chemicals, or finishing agents

112

which cause deterioration of webbing in normal storage.

Thread not of nylon cord specified.

113

Mesh configuration and dimensions nonconforming.

114

Frame configuration and composition nonconforming.

115

Stitches not continuous; not properly maintained thread tension;

116

evidence of loose stitches.

Stitching pattern nonconforming: frame webbing and superimposed

117

mesh webbings not stitched as specified.

Friction pads not same type of webbing, not located or attached as

118

specified.

Minor:

201

Size identification web insertions not of assigned color; not

inserted into body as specified.

Color of webbing nonconforming.

202

4.6 Tests.

4.6.1 Spacing of slots. Measurement of slot spacings shall be made on eight webbing

samples. The exact centers of two consecutive slots on each sample shall be marked on the

selvage, and the distance between marks measured with a metal tape graduated in 1/16 inch

(see table I).

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |