|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-26547C

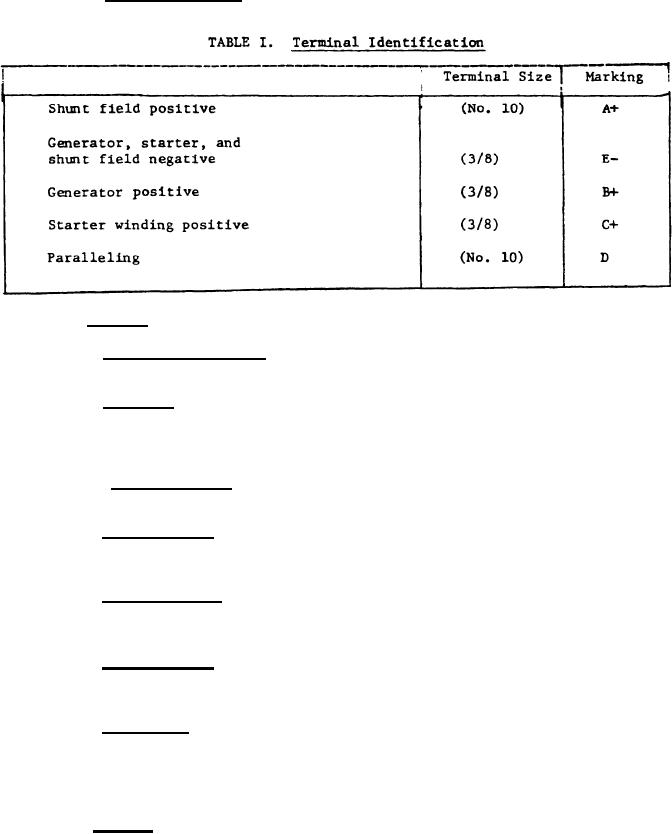

The terminals shall be located and marked as

3.4.7.1 Terminal marking.

shown on Figure 3.

3.4.8

Brushes.

Brush accessibility. Brushes shall be accessible for inspection

3.4.8.1

and replacement when brush cover bands are removed (see Figure 3).

3.4.8.2 Brushfit. The face of each brush shall contact its commutator

100 per cent in the direction of rotation and for at least 75 per cent of

brush dimension parallel to the shaft. There shall be no evidence of grooving

or other surface damage to the face of the brush.

Cartridge type. The brushes in cartridge-type brush assemblies

3.4.8.3

shall not rotate when mounted.

3.4.8.4 Spare brushes. All spare brushes shall be formed to a radius

equal to the radius of the new commutator and shall be identical to the

corresponding brushes approved by the qualification tests.

3.4.8.5 Brush position. The brush rigging shall be fixed position (non-

shifting) type. The brush rigging position shall be identical for all genera-

tors of the same model number made by the same manufacturer.

3.4.8.6 Brush marking. Each brush shall have a diagonal groove in the

anti-drive side, from the contact surface to a point on the front or back of

the brush, which indicates 100 per cent of allowable wear.

3.4.8.7 Brush type. Brushes shall be of the immediate filming type which

do not require prolonged operation of the starter-generator to establish an

altitude protective film on the commutator. Rivets used to secure the leads

to the brushes shall be silver soldered to the pigtail at point of riveted

contact.

* 3.4.9

Cooling. For generator operation, cooling air shall be provided

through a 2 inch diameter duct which shall not be a part of the starter-

generator. The starter-generator shall include provisions for entrance of

external air for cooling purposes through the anti-drive end, or brush access

windows. When cooling air is required to enter through the anti-drive end,

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |