|

|||

|

|

|||

| ||||||||||

|

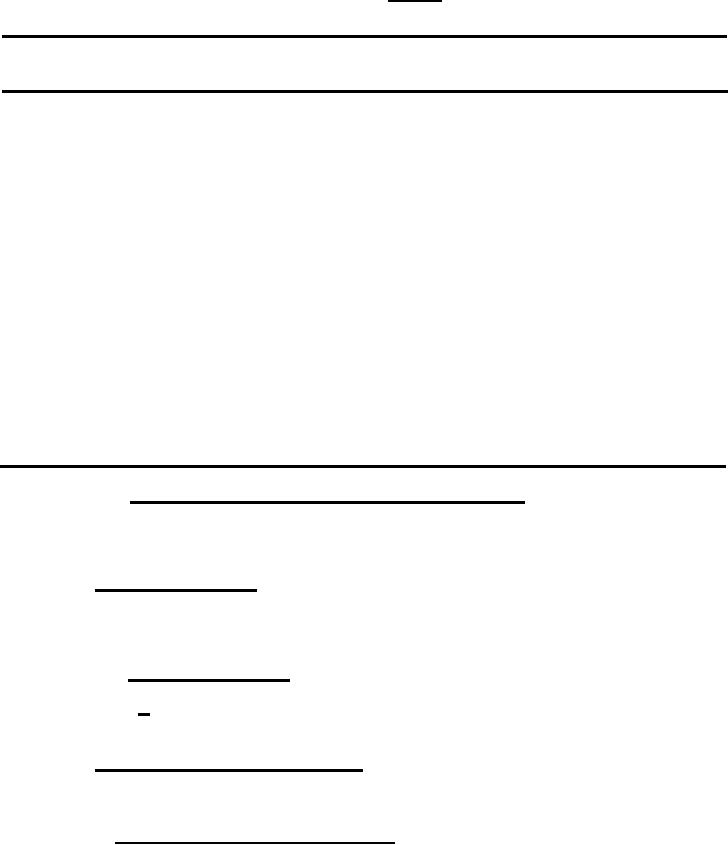

|  MIL-S-29398C(MC)

Table II.

Tests

1st

Quality

Production

Article

Conformance

Sampling

(4.4)

Test

Para

(4.3)

(4.5)

Nondestructive

4.7.3

x

x

x

examination

Cyclic load

4.7.2.2

x

tests

Proof load

4.7.2.3

x

x

tests

Ultimate

4.7.2.4

x

x

breaking

strength load

tests

Elongation

x

4.7.2.5

x

tests

Net length

4.7.2.6

x

x

tests

*4.7.2.4 Ultimate breaking strength load tests. The component

assemblies shall sustain not less than the ultimate loads cited in

3.3 and 3.4. Inability to meet the specified load shall constitute

failure of this test.

4.7.2.5

Elongation test. The sling legs assemblies shall not be

elongated in excess of 7.0 inches at completion of 5 minutes holding

time during the proof load test of 4.7.2.3. Elongation in excess of

7.0 inches shall constitute a failure.

*4.7.2.6 Net length test. The length of the sling leg assemblies

measured between the load bearing surfaces while sling leg assembly

is under 100 + 10 pounds of tension shall be 144 inches +1.5 inches

after the proof load test of 4.7.2.3.

4.7.3 Quality conformance tests. Each sling system shall have

components tested in accordance with the following. Records of

tests shall be submitted with each sling system.

4.7.3.1 Nondestructive

examination. Inability of any component

to pass the acceptance criteria (Table I) shall constitute failure

of this test.

9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |